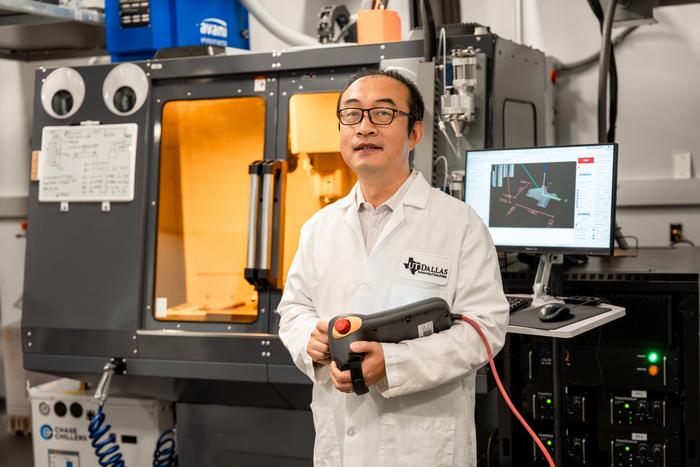

Dr. Wei Li, an innovative researcher at The University of Texas at Dallas, is embarking on a groundbreaking project aimed at tackling some of the most significant challenges of human colonization beyond Earth. With the support of a substantial NASA grant, Li is developing a virtual welding platform specifically designed to master the intricacies of constructing permanent structures on the moon and potentially Mars. The quest to colonize these extraterrestrial terrains demands that we arrive at effective methods for building habitats capable of withstanding extreme environments.

In recent years, interest in lunar and Martian colonization has surged, driven by advancements in space exploration and a renewed emphasis on sustainable human presence in outer space. With missions planned for the moon and Mars in the near future, the necessity for establishing safe and functional habitats becomes paramount. Dr. Wei Li’s research promises to be a vital contribution to this endeavor, as he focuses on developing welding techniques suited for the unique conditions that exist on these celestial bodies.

The NASA Early Stage Innovations grant, valued at up to $750,000 over three years, underscores the significance of Li’s research, as he is among a select group of six researchers nationwide awarded the 2024 annual recognition. This grant is intended to accelerate transformative technologies that carry inherent risks yet promise high rewards, aligning perfectly with the aspirations of space exploration.

Li highlights three core challenges associated with welding on the moon. Firstly, the extreme temperature fluctuations pose a serious concern for maintaining the integrity of materials. Temperatures can vary dramatically between extremes of approximately minus 387 degrees Fahrenheit and 260 degrees Fahrenheit, testing the limits of conventional materials and processes. Secondly, the moon’s thin atmosphere results in high vacuum conditions, which can adversely affect the behavior of materials during welding. Lastly, the moon’s gravitational conditions—only one-sixth that of Earth—add an additional layer of complexity to the welding process, demanding a fresh perspective and innovative solutions.

The implications of Li’s research extend beyond mere academic inquiry; they resonate deeply with NASA’s long-term exploration objectives. Li acknowledges the difficulty of establishing manufacturing facilities on the moon akin to those on Earth. However, his vision extends toward a practical approach: transporting metal components from Earth to the moon and utilizing advanced welding technologies in space to assemble larger structures. This method could provide the foundational framework necessary for establishing a sustainable human community on the lunar surface.

Li’s virtual welding platform is central to his research. It employs an advanced multiple-physics modeling approach to simulate the welding processes and the mechanical properties of welded joints under lunar conditions, including electrical arc, laser, and electron-beam welding. This platform not only aims to replicate the specific challenges posed by the moon’s environment but also provides a proactive means to develop best practices for construction in space.

Among the state-of-the-art equipment employed in the research is a custom-built directed energy deposition machine. This machine, primarily used for the additive manufacturing of metals, allows Li to explore various welding methodologies and their applications in real-world scenarios. The potential applications of Li’s research extend into the realm of 3D printing as well, leveraging techniques such as fused deposition modeling that could revolutionize how nonmetallic parts are manufactured in space.

Collaboration is at the heart of Li’s project, which involves close cooperation with NASA researchers, including Dr. Fredrick Michael from NASA’s Marshall Space Flight Center. This partnership enriches the research with invaluable insights from seasoned professionals in space exploration and engineering, ensuring that the practical aspect of the project remains grounded in real-world applications and feasibility.

Validating the simulation framework is paramount to the success of Li’s research, and he plans to bridge the gap between theoretical models and actual results through experiments conducted in both space-based and terrestrial environments. Drawing upon historical data from Skylab, the first U.S. space station, Li aims to substantiate his findings and potentially expand the model’s applicability to other extraterrestrial environments, including Mars and the International Space Station.

Ultimately, Dr. Wei Li’s research represents a significant stride toward making human colonization of the moon and Mars a tangible reality. By addressing the formidable challenges of welding in extreme environments, his work could lay the groundwork for safer and more efficient construction practices in space. This research not only has the potential to enhance our understanding of materials science but also holds the key to unlocking sustainable human presence on other planets, marking a groundbreaking leap forward in our quest to become a multi-planetary species.

The urgency of Dr. Li’s research cannot be understated; with ambitious goals set for lunar and Martian missions, the time to innovate is now. As humanity stands on the brink of cosmic exploration, researchers like Dr. Wei Li are crafting the tools and techniques that will enable us to build our future among the stars.

Subject of Research: Lunar Welding Techniques

Article Title: Developing Welding Techniques for Extraterrestrial Construction

News Publication Date: October 2023

Web References: NASA Early Stage Innovations

References: University of Texas at Dallas

Image Credits: The University of Texas

Keywords

Lunar colonization, welding technology, NASA grant, extraterrestrial habitats, Dr. Wei Li, mechanical engineering, space exploration, simulation framework, materials science, 3D printing.