In a groundbreaking advancement in materials science, researchers at North Carolina State University have unveiled a revolutionary technique that harnesses the power of lasers to create ultra-high temperature ceramics. This innovative method promises to enhance the performance of technologies in fields ranging from nuclear energy production to aerospace engineering. The primary focus of the study was on the ultra-high temperature ceramic known as hafnium carbide (HfC), which is renowned for its superior heat resistance and mechanical properties.

Traditional production methods for HfC involve sintering processes that require exorbitant temperatures exceeding 2,200 degrees Celsius. This necessitates the use of large furnaces, which can be both time-consuming and energy-intensive. In contrast, the newly developed laser sintering technique has drastically streamlined this process, allowing for the production of high-quality ceramics in a fraction of the time while consuming significantly less energy. Researchers suggest that the laser-based approach is not only faster but also easier to implement, paving the way for a new era of ceramic materials development.

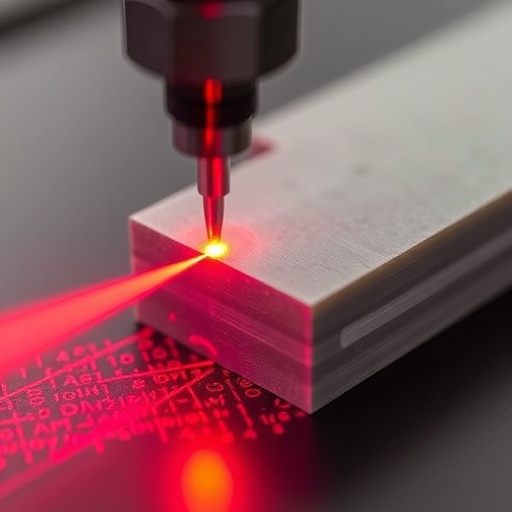

The technique begins with the application of a 120-watt laser on a liquid polymer precursor, performed in a controlled inert atmosphere, such as a vacuum chamber or a chamber filled with argon gas. By directing the laser at the liquid precursor, researchers effectively initiate a sintering process that converts the liquid polymer into a solid ceramic material. This method can be applied in two significant ways, contributing to the versatility and durability of materials used in extreme environments.

One primary application is in the creation of coatings for existing materials, particularly carbon composites that are prevalent in advanced hypersonic technologies. In this scenario, the liquid precursor is applied directly onto the surface of the material, and the localized laser sintering reduces the risk of structural damage that would typically occur from the intense heat of conventional sintering. This innovative approach not only preserves the integrity of the underlying materials but also enhances their thermal protection and oxidation resistance.

The second application involves the integration of this process with additive manufacturing, commonly known as 3D printing. By fine-tuning the laser sintering procedure, researchers can develop complex three-dimensional structures. The process begins with a digital model of the desired object, which is then sliced into layers. The laser traces the first layer of the design within the liquid precursor, rapidly converting it into ceramic, before the platform lowers to continue the process layer by layer. This method represents a significant leap forward in the realm of additive manufacturing, where precision and material performance are paramount.

What makes the laser sintering technique particularly remarkable is its efficiency. Unlike traditional methods which may take hours or even days for the drying and curing processes, laser sintering enables the creation of ceramic structures and coatings in mere seconds or minutes. This contrasts sharply with the conventional practices observed in the field, where the conversion rates of precursor material into ceramic can be as low as 20% to 40%. The laser technique boasts a conversion efficiency of at least 50%, leading to less waste and a more sustainable manufacturing approach.

Furthermore, the portable nature of this laser sintering technique adds an additional layer of practicality. While traditional sintering requires cumbersome, large-scale furnaces, the new method only necessitates equipment such as a vacuum chamber or additive manufacturing setup. This portability could facilitate a wide range of practical applications in various sectors, from aerospace to energy production, presenting opportunities for both public and private partnerships.

In experimental tests, scientists successfully demonstrated the ability to produce crystalline, phase-pure HfC using the proposed laser sintering technique from a liquid polymer precursor for the first time. The unprecedented quality achieved is a clear indication of the potential applications and advancements this technology could offer, especially in areas where materials must endure extreme conditions, such as jet engines, rocket nozzles, and nuclear reactors.

Researchers also examined the adhesive qualities of the HfC coatings when applied to carbon-fiber reinforced carbon composites. The results indicated strong adhesion characteristics and uniform coverage, which are essential attributes for thermal protection systems designed to enhance performance and durability in harsh environments. This capability is incredibly valuable as it opens the door for enhanced engineering applications not only in aerospace but in various industrial sectors requiring reliable high-temperature materials.

As the study progresses, the implications of this innovative laser sintering technique could reshape the landscape of ceramics and material science. The potential for collaboration with industry leaders and academic institutions can lead to further research and development projects aimed at exploiting the benefits of laser-sintered ceramics. This could lead to a new generation of advanced materials that meet the demands of the high-performance world we live in today.

Cheryl Xu, a co-corresponding author of the study and a professor of mechanical and aerospace engineering at NC State, expresses excitement about these advancements. She emphasizes that the research team is open to collaborations that would help transition this burgeoning technology into practical applications. The future of ceramics appears bright as the fusion of innovative science and engineering continues to advance.

The research findings and technological advancements have been published in the Journal of the American Ceramic Society, providing a detailed account of the methodologies and outcomes of this innovative work. The authors hope that by sharing this knowledge, they can inspire further research and adoption of these techniques across various industries as the demand for high-performance materials continues to grow.

As the world progresses towards more complex and demanding technologies, the development of ultra-high temperature ceramics through this sophisticated laser sintering method exemplifies the intersection of innovation and practicality that fuels the evolution of material sciences.

Subject of Research: Ultra-high temperature ceramics

Article Title: Synthesis of Hafnium Carbide (HfC) via One-Step Selective Laser Reaction Pyrolysis from Liquid Polymer Precursor

News Publication Date: 14-May-2025

Web References: https://ceramics.onlinelibrary.wiley.com/doi/full/10.1111/jace.20650

References: 10.1111/jace.20650

Image Credits: North Carolina State University

Keywords

Laser sintering, hafnium carbide, ultra-high temperature ceramics, additive manufacturing, nuclear energy, aerospace engineering, carbon composites, materials science, innovative technology.