In the rapidly evolving field of 3D printing, research continues to unveil the profound impact of design choices on material properties and applications. Notably, a groundbreaking study by Li and Ma delves deep into the mechanical properties of 3D printed porous structures dictated by their topological configurations. This research aligns with increasing demands for advanced materials that balance strength, flexibility, and lightweight characteristics, catering to multiple industries including aerospace, automotive, and biomedical engineering.

The study highlights how manipulating the geometric arrangements within porous structures can yield substantial variations in mechanical performance. This is particularly significant as the manufacturing landscape transitions toward complex geometries that traditional materials processing methods cannot accommodate. Through methodical experimentation, the authors demonstrate that varying the topology, or the arrangement of elements in these structures, can ultimately enhance or compromise their structural integrity.

At the heart of Li and Ma’s investigation is the need to leverage computational models and simulations to predict material behavior before physical prototypes are created. By employing advanced simulation tools, researchers can explore a multitude of design variations in a virtual environment. This predictive capability not only accelerates the design process but also minimizes material waste and financial costs associated with traditional trial-and-error methods.

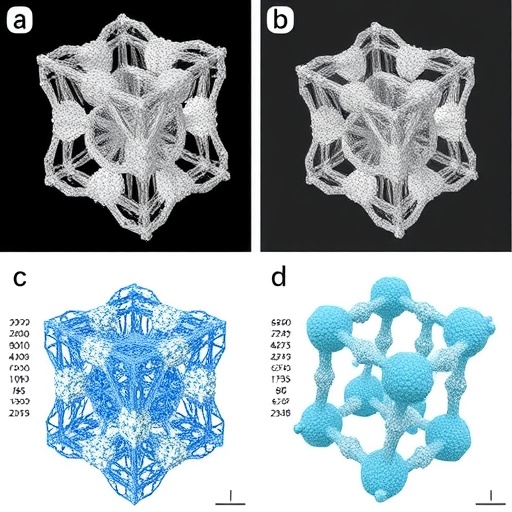

The authors meticulously analyzed several topological configurations, such as lattice structures. These lattice designs consist of interconnected struts that form a three-dimensional network, allowing for a high strength-to-weight ratio. This specific topology is particularly advantageous in applications requiring lightweight materials with excellent load-bearing capabilities. The study shows that specific configurations can significantly influence compressive strength, flexibility, and failure modes.

Intriguingly, the research also underscores the relationship between porosity and mechanical performance. Increasing the porous nature of these structures typically enhances their flexibility; however, it can concurrently diminish strength. Thus, finding an optimal balance is crucial. Li and Ma advocate for a strategic approach to design that not only maintains necessary material attributes but also tailors properties to the specific performance requirements of the intended application.

The findings extend beyond merely theoretical applications. Practical implications abound for various industries that could benefit from lightweight, durable materials—so much so that these 3D printed structures could revolutionize product lifespan and performance across multiple fields. For instance, in the biomedical sector, customized implants designed with optimized porosity could promote better integration with surrounding tissues, enhancing healing outcomes while minimizing adverse reactions.

Moreover, aircraft manufacturers could leverage these developed materials to reduce overall vehicle weight, leading to improved fuel efficiency and reduced carbon emissions. Such a transformation is not just an incremental improvement; it signifies a shift toward more sustainable manufacturing practices. As industries grapple with environmental concerns, the ability to produce customized, lightweight materials with superior mechanical properties signifies a critical advancement.

An essential aspect of conducting such research revolves around the evaluation of mechanical properties post-manufacturing. Without an accurate assessment of how topological changes influence performance under real-world conditions, theoretical designs remain untested. The hands-on experimentation combined with computational predictions fosters a comprehensive understanding of how these porous structures behave under various loads, setting the foundation for more robust engineering practices.

The research also paves the way for future inquiries. It opens up avenues for investigating alternative materials beyond plastics, such as metals or bio-composites. Exploring these options could yield even more revolutionary results, contributing to fields where durability and biocompatibility are paramount. Each new material possesses unique mechanical characteristics and interactions based on its topology, further encouraging a multi-disciplinary approach to materials science.

In the pursuit of enhancing mechanical properties through design optimization, interdisciplinary collaboration emerges as a key strategy. The interaction between material scientists, engineers, and computational experts is necessary to bridge the gap between theory and practical application. As the field advances, fostering teamwork could yield more innovative solutions by merging diverse expertise toward common goals.

Ultimately, Li and Ma’s study is more than just a series of mathematical evaluations and mechanical tests; it’s a clarion call for the potential transformation of manufacturing processes. As industries step into a world where customization is the norm, the significance of their research cannot be understated. By strategically exploiting topological configurations in 3D printing, they have opened a Pandora’s box of possibilities that could redefine the parameters of material science and engineering.

Looking forward, the implications of these findings are profound. They position 3D printing not merely as a tool for prototyping but as an essential component in the full-fledged production of functional components. As this technology continues to mature, the intersection of design and mechanical engineering will likely hold the key to breakthroughs in various sectors, potentially leading to unprecedented innovations that can reshape our understanding of what is feasible in material properties.

In summary, the research conducted by Li and Ma puts forth critical insights into the relationship between design topology and mechanical properties in 3D printed structures. With the integration of computational techniques alongside experimental validations, the study sets the stage for future explorations that could yield a new generation of functional materials, highly tailored to meet the specific demands of diverse applications. As industries progressively adopt these advanced techniques, the landscape of manufacturing will undoubtedly evolve, emphasizing efficiency, sustainability, and superior material performance.

Subject of Research: Topological configurations and their effects on the mechanical properties of 3D printed porous structures.

Article Title: Effect of topological configuration on mechanical properties for 3D printed porous structures.

Article References:

Li, Y., Ma, X. Effect of topological configuration on mechanical properties for 3D printed porous structures.

Sci Rep 15, 35509 (2025). https://doi.org/10.1038/s41598-025-19618-y

Image Credits: AI Generated

DOI: 10.1038/s41598-025-19618-y

Keywords: 3D printing, porous structures, mechanical properties, topology, materials science, simulation, engineering.