Research into the environmental implications of creosote-treated railroad ties has gained significant attention, particularly in the context of energy recovery and management of industrial waste. The recent study by Borsuk et al. delves into innovative methodologies for the end-of-life management of these materials, particularly their potential for energy recovery when utilized in cement kiln installations. This research not only sheds light on the effectiveness of computational fluid dynamics (CFD) modeling in predicting the behavior of such waste materials but also highlights the pressing need for sustainable practices in industrial processes.

Creosote, a wood preservative derived from the distillation of tar, has been traditionally used to prolong the lifespan of railroad ties. Despite its effectiveness, the use of creosote is coupled with a series of environmental challenges. When these ties reach the end of their useful life, the question of safe disposal becomes paramount. Borsuk and colleagues explore the potential of repurposing these ties as a source of energy rather than relegating them to landfills, which could pose a risk of leaching harmful compounds into the soil and water systems.

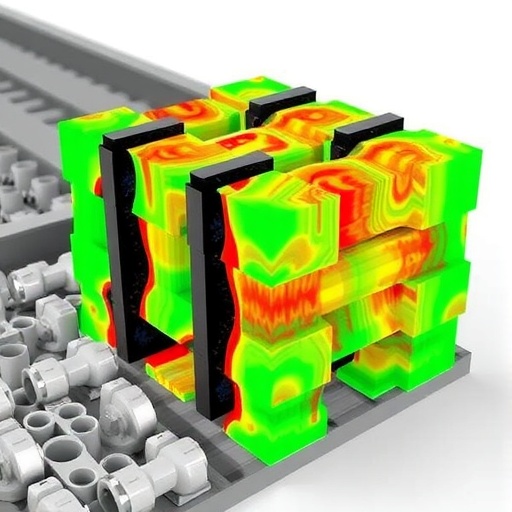

The study emphasizes the use of advanced modeling techniques, particularly CFD, to understand the combustion characteristics of creosote-treated railroad ties within a cement kiln environment. By simulating the combustion process, the researchers can predict emissions, fuel behavior, and overall energy output, making it a valuable tool in waste management strategies. CFD modeling provides insights into how different operational conditions affect the energy recovery process, allowing for the optimization of combustion parameters for better performance and lower emissions.

One of the primary goals of this research is to assess the viability of integrating creosote-treated ties into existing cement kiln operations. Cement kilns are among the largest industrial sources of CO2 emissions globally, and incorporating alternative fuels such as treated wood can potentially reduce the carbon footprint of cement production. The findings indicate that careful consideration of feedstock characteristics, including the chemical composition of the creosote, is essential in determining the efficiency and sustainability of energy recovery.

Moreover, the study outlines the potential energy contributions from creosote-treated ties in cement kilns. By analyzing the calorific value of these materials, the authors demonstrate that they can serve as a significant alternative to traditional fossil fuels. This not only addresses the waste problem associated with expired railroad ties but also presents a pathway to reduce dependency on non-renewable energy sources. As cement production demands continue to rise globally, developing innovative waste-to-energy solutions becomes increasingly critical.

The authors acknowledge the challenges of implementing such strategies on a larger scale. Regulatory frameworks concerning hazardous materials present barriers that must be navigated carefully. However, the results from the CFD simulations provide a compelling argument for policymakers to consider the energy recovery potential of creosote-treated ties as a viable option within a circular economy model. This could lead to revised regulations that facilitate the sustainable use of treated waste materials in industrial applications.

In addition to addressing waste management, this research aligns with broader climate goals. Reducing the environmental impact of cement production is vital for meeting international climate commitments. The study’s findings could serve as a catalyst for further research into alternative fuels and the integration of innovative waste treatment methodologies in traditional industries. By leveraging sustainable practices, industries can move towards not only compliance with regulations but also contribute positively to environmental conservation efforts.

The collaborative nature of the research team, comprising experts from various fields, signifies the interdisciplinary approach necessary to tackle complex environmental issues. Their combined expertise in chemical engineering, environmental science, and waste management enhances the research’s credibility and applicability. Furthermore, the approach taken by the authors sets a precedent for future studies aimed at exploring similar waste management opportunities across different industrial sectors.

Engagement with stakeholders, including industry professionals and environmental advocates, is essential to successfully implement the findings of this study. Dialogue between researchers and practitioners can help bridge the gap between theoretical modeling and practical application. Ensuring that the energy recovery systems are economically viable is as important as their environmental benefits. As industries continue to evolve, multi-faceted strategies for fuel management will be essential in achieving both economic and ecological objectives.

In conclusion, the study by Borsuk et al. showcases the potential of advanced modeling techniques to revolutionize the management of industrial waste. By focusing on the energy recovery of creosote-treated railroad ties in cement kiln installations, the authors present a compelling case for innovative waste-to-energy solutions. Through ongoing research and collaboration across disciplines, we can advance towards a more sustainable industrial future, where waste is seen not as a burden but as a valuable resource. This study not only contributes to the academic discourse on waste management but also presents actionable insights for industries looking to adopt greener practices.

Thus, recognizing the importance of integrating sustainable waste management practices, this research opens up new possibilities for utilizing creosote-treated materials within energy-intensive operations. With continued exploration into the capabilities of CFD modeling and the optimization of energy recovery processes, there is immense potential for transforming how industries approach waste. The future of waste management lies in innovation, collaboration, and a commitment to sustainability, as highlighted in the pivotal work of Borsuk and his colleagues.

Subject of Research: End-of-Life Management of Creosote-Treated Railroad Ties for Energy Recovery

Article Title: End-of-Life Management of Creosote-Treated Railroad Ties for Energy Recovery in Cement Kiln Installation: A CFD Modelling Approach

Article References:

Borsuk, G., Wydrych, J., Wzorek, M. et al. End-of-Life Management of Creosote-Treated Railroad Ties for Energy Recovery in Cement Kiln Installation: A CFD Modelling Approach. Waste Biomass Valor (2025). https://doi.org/10.1007/s12649-025-03331-y

Image Credits: AI Generated

DOI: 10.1007/s12649-025-03331-y

Keywords: creosote-treated railroad ties, energy recovery, cement kiln, CFD modeling, waste management, sustainability, circular economy.