In recent years, the environmental challenges faced by coal mining operations have become a growing concern, particularly regarding harmful emissions such as carbon monoxide (CO). A breakthrough approach to tackling this issue has been reported in a recent study by Zhai et al., which focuses on the development of copper-loaded adsorbents designed to achieve efficient CO elimination in the upper corners of coal mines. This innovative technology not only addresses the urgency of pollution control but also explores the implications for resource management in these often-overlooked areas of mining operations.

Carbon monoxide is a colorless, odorless gas that can pose serious health risks to miners, necessitating effective removal strategies within confined spaces. Traditional methods of ventilation and gas monitoring have proven inadequate in fully addressing the direct hazards presented by CO, especially in upper corners of coal mines where airflow may be limited. The novel approach outlined by Zhai and colleagues introduces a targeted solution that could significantly enhance safety and operational efficiency in these hazardous environments.

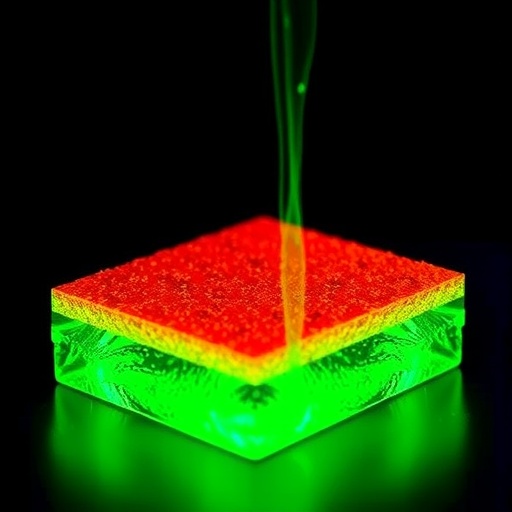

The researchers conducted extensive experiments to assess the performance of copper-loaded adsorbents in trapping and eliminating CO from the air. By utilizing copper compounds known for their strong adsorption capacities, they aimed to create an efficient material capable of binding CO molecules. The process involved synthesizing various copper materials that were then tested under controlled conditions, simulating the specific atmospheres typically found in coal mine upper corners. These studies revealed surprisingly high efficiency rates under real-world simulated conditions, showcasing the adorbents’ capabilities.

One of the key findings from the study was that the performance of these copper-loaded adsorbents varied based on several factors, including temperature, pressure, and the concentration of CO in the environment. The researchers observed that the adsorbents maintained high efficiency even in challenging conditions, indicating their promise as a robust solution for CO removal in mining applications. Furthermore, the researchers highlighted the potential adaptability of these adsorbents, which could be engineered to meet specific operational needs and enhance air quality within mining enterprises.

Additionally, the resource implications of utilizing such copper-loaded adsorbents are significant. Given the ongoing global concern over the depletion of natural resources, mining operations are particularly scrutinized for their environmental footprint. By developing materials that not only remove hazardous gases but do so using readily available materials, the study suggests a pathway towards a more sustainable mining process. The copper used in the adsorbents could be sourced from mining waste, thereby creating a circular economy model within the industry.

The successful application of these adsorbents could revolutionize the approach to air quality management in coal mining. Enhanced safety protocols may lead to improved working conditions for miners, reducing the risks associated with exposure to toxic gases. Furthermore, a wider implementation of this technology could raise industry standards for air quality, leading to potential regulatory changes that prioritize worker safety and environmental health.

In terms of scalability, the study provides a feasible framework for integrating copper-loaded adsorbent technology into existing mining operations. The researchers indicated that with further investment, these materials could be manufactured at scale, making them an accessible alternative for many coal mining companies aiming to mitigate emissions effectively. The long-term viability of this technology hinges not only on performance but also on cost-effectiveness, which will be a critical factor in determining its adoption in the industry.

Furthermore, while this study provides groundbreaking insights, it also opens the door for further research into various other metal-loaded adsorbents. The potential for innovation extends beyond copper to include a range of metals and materials, each with unique properties that could contribute to improved gas removal techniques across different contexts. This exploration could enhance the overall arsenal of solutions available for tackling mining-related emissions.

While the findings are indeed promising, the research team emphasized the importance of continued investigation and real-world testing before fully implementing this technology in operational settings. Field trials will be essential to assess the long-term effectiveness and reliability of copper-loaded adsorbents in various mining environments. Moreover, gaining insights from practical applications can uncover unforeseen challenges, refining the technology to meet the specific needs of diverse coal mining operations.

As the coal mining industry faces increasing scrutiny regarding its environmental impact, the contributions of Zhai et al. underscore a critical intersection between resource utilization and pollution control strategies. Innovations like copper-loaded adsorbents not only aim to enhance worker safety but also usher in a more responsible and sustainable future for one of the world’s oldest industries. The study foregrounds a growing recognition that technological advancements are essential in mitigating the environmental challenges associated with fossil fuel extraction.

In conclusion, the research by Zhai and colleagues serves as an important reminder of the pivotal role that innovation plays in addressing environmental concerns while ensuring the safety and efficiency of mining operations. As industries continue to seek sustainable practices, the journey towards cleaner coal mining processes is poised to be shaped by such pioneering studies. With hopes high for the widespread adoption of copper-loaded adsorbents, the coal mining sector may soon take significant strides toward balancing operational needs with ecological stewardship.

Ultimately, the promising outcomes from this study suggest that advancements in material science and engineering can significantly contribute to environmental health. By focusing on the development of cost-effective and efficient gas removal technologies, the coal mining industry can take definitive steps toward a safer and more sustainable operational framework, adhering to both regulatory demands and responsible mining practices.

Subject of Research: The development and efficacy of copper-loaded adsorbents for CO elimination in coal mines.

Article Title: Copper-Loaded Adsorbents for Efficient CO Elimination in Coal Mine Upper Corners: Performance and Resource Implications.

Article References:

Zhai, X., Hou, Q., Liu, X. et al. Copper-Loaded Adsorbents for Efficient CO Elimination in Coal Mine Upper Corners: Performance and Resource Implications.

Nat Resour Res (2025). https://doi.org/10.1007/s11053-025-10554-2

Image Credits: AI Generated

DOI:

Keywords: Copper-loaded adsorbents, CO elimination, coal mine safety, environmental impact, sustainable mining.