In a groundbreaking development poised to reshape the landscape of sustainable energy, researchers at Fuzhou University have engineered an innovative catalyst system that significantly advances the electrochemical reduction of carbon dioxide (CO₂) into ethanol. This novel catalyst, which incorporates ultrasmall palladium nanoparticles meticulously anchored on a zirconium phosphate substrate, represents a pivotal leap forward in carbon capture technologies, offering an efficient and highly selective pathway to convert CO₂—a major greenhouse gas—into value-added renewable fuels. The findings, meticulously detailed in the latest issue of Frontiers in Energy, introduce compelling new possibilities for addressing the dual challenges of mitigating climate change and developing sustainable fuel alternatives.

The electrochemical reduction of CO₂ presents itself as a frontier technology with immense potential. By transforming this abundant greenhouse gas into fuels and valuable chemicals, it tackles the urgent need for carbon management while simultaneously contributing to renewable energy production. Traditional noble-metal catalysts such as palladium, platinum, and gold are renowned for their catalytic activity and stability in facilitating CO₂ reduction reactions. However, such catalysts often exhibit limited selectivity, predominantly generating single-carbon (C1) products like carbon monoxide or formic acid. Additionally, the high economic and resource costs associated with noble metals compel scientists to explore ways to maximize their catalytic efficiency while minimizing usage.

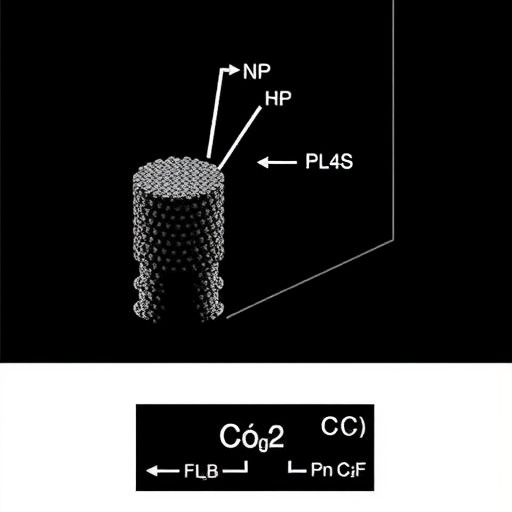

Addressing these critical challenges, the Fuzhou University team has synthesized a new catalyst architecture featuring ultrasmall palladium nanoparticles embedded within a zirconium phosphate (Zr₃(PO₄)₄) matrix. This precise nanoscale engineering enhances metal-support interactions, dramatically improving catalytic performance. Under experimentally optimized conditions, their catalyst demonstrated an exceptional Faradaic efficiency of 92.1% for the conversion of CO₂ directly to ethanol at a reduction potential of –0.8 volts relative to the reversible hydrogen electrode (RHE). Moreover, the catalyst achieved a noteworthy peak ethanol current density measuring 0.82 mA per cm² of electrode surface, metrics that underscore its practical potential for industrial scaling.

Integral to these advancements were computational studies leveraging density functional theory (DFT), a quantum mechanical modeling method that elucidates the electronic mechanisms underpinning catalytic processes. The DFT calculations revealed that the strong interaction between the palladium nanoparticles and the zirconium phosphate support stabilizes adsorbed carbon monoxide intermediates. This stabilization is critical as it facilitates efficient CO coupling—a key mechanistic step driving the selective formation of ethanol over competing pathways. The unique electronic environment created by the metal-support interface effectively lowers the energy barriers associated with complex multi-step reactions, enabling higher product yields and selectivity.

Synthesis of these ultrasmall palladium nanoparticles employed advanced wet-chemical methods and controlled nucleation techniques to ensure uniform particle size distribution below 5 nanometers. This ultrasmall dimension not only enhances the active surface area available for catalytic reactions but also alters the electronic structure of the palladium, resulting in increased reactivity and improved binding properties for key intermediates in the CO₂ reduction pathways. The choice of zirconium phosphate as a support is equally strategic, providing chemical robustness, proton conductivity, and an ideal platform for dispersing palladium clusters while mitigating agglomeration and deactivation during operation.

Historically, electrocatalysts for CO₂ reduction have faced significant hurdles related to product selectivity, stability, and overall efficiency. Many catalysts deliver mixtures of products that complicate downstream separation and industrial application. This study’s clear demonstration of producing ethanol—a high-value, energy-dense, two-carbon alcohol—with such high specificity and Faradaic efficiency signifies a major milestone. Ethanol itself is a widely used fuel additive with established infrastructure and high compatibility with existing energy systems, making this catalytic approach particularly attractive from a commercial standpoint.

The implications of this work stretch beyond mere carbon capture into the realm of sustainable chemical manufacturing and renewable fuel generation. By harnessing the intrinsic properties of ultrasmall nanoparticles and their synergistic interaction with chemically robust supports, this research highlights a paradigm shift in catalyst design. It suggests that careful atomic- and nanoscale engineering may unlock new catalytic pathways that were previously inaccessible, thereby offering solutions that are both economically viable and environmentally sustainable.

From a materials science perspective, the detailed characterization of the catalyst using advanced electron microscopy and spectroscopy techniques confirmed the ultrasmall size, uniform dispersion, and stability of the palladium nanoparticles on the zirconium phosphate. These insights provide a foundation for understanding structure-function relationships critical for optimizing catalytic behavior. Furthermore, the durability tests indicated sustained catalytic performance over extended operational periods, an essential criterion for real-world application.

This pioneering work underscores the value of integrating experimental and theoretical approaches to accelerate the discovery and optimization of efficient electrocatalysts. The synergy between precise nanostructure synthesis, thorough electrochemical evaluation, and predictive computational modeling exemplifies a holistic strategy for tackling one of today’s most pressing environmental challenges—transforming excess atmospheric CO₂ into useful chemical products.

Looking ahead, the research team has expressed intentions to further refine the catalyst architecture to enhance its scalability and adapt the system for integration with renewable electricity sources. Such advances would potentially enable decentralized production of ethanol fuel from CO₂, significantly reducing greenhouse gas emissions and dependence on fossil-derived fuels. Moreover, the principles demonstrated here may catalyze future innovations spanning other catalytic systems and electrochemical processes targeting sustainable energy and chemical transformations.

Ultimately, the breakthrough emphasizes the transformative potential of nanotechnology and materials engineering in combating climate change through innovative catalytic solutions. By creating catalysts that achieve unprecedented efficiency and selectivity for converting a problematic greenhouse gas into a valuable fuel, this research points the way toward a cleaner, more sustainable energy future. The study stands as a beacon for the scientific community, inspiring renewed focus on multidisciplinary strategies for environmental stewardship and renewable fuel development.

For those eager to delve into the technical particulars and foundational data supporting these findings, the full research article is available in Frontiers in Energy and can be accessed online via: https://journal.hep.com.cn/fie/EN/10.1007/s11708-025-1025-1. Continued exploration and refinement of this catalyst system may soon unlock new chapters in sustainable chemistry and energy conversion.

Subject of Research: Not applicable

Article Title: Ultrasmall palladium nanoparticles supported on zirconium phosphate for electrochemical CO2 reduction to ethanol

News Publication Date: 15-Jul-2025

Web References: https://journal.hep.com.cn/fie/EN/10.1007/s11708-025-1025-1

Image Credits: HIGHER EDUCATION PRESS

Keywords

Energy