In a groundbreaking advancement poised to transform the field of electrochemical carbon dioxide conversion, researchers from the Technical University of Denmark (DTU), Ecole Polytechnique Fédérale de Lausanne (EPFL), and the European Synchrotron Radiation Facility (ESRF) have unveiled a novel two-dimensional X-ray diffraction imaging technique. This state-of-the-art, in-operando imaging approach allows scientists to peer deeply into the working heart of CO₂ electrolyzers, elucidating with unprecedented spatial precision the dynamic processes governing their performance and degradation. By capturing real-time, spatially resolved maps of salt formation and water transport within the membrane-electrode assembly (MEA), these insights pave the way for designing next-generation devices with extended operational lifetimes and enhanced efficiency.

At the core of this research is the challenge posed by salt accumulation inside CO₂ electrolyzers—a formidable barrier hindering their scale-up for industrial application. Salt precipitation, primarily composed of bicarbonates originating from electrochemical reactions, tends to obstruct CO₂ pathways within the porous gas diffusion layer. This blockage not only compromises reactant transport but also accelerates catalyst deactivation, culminating in rapid performance decay. Previous characterization techniques, relying on averaged signals from entire devices, lacked the spatial resolution needed to discern where and how these detrimental processes initiate and evolve.

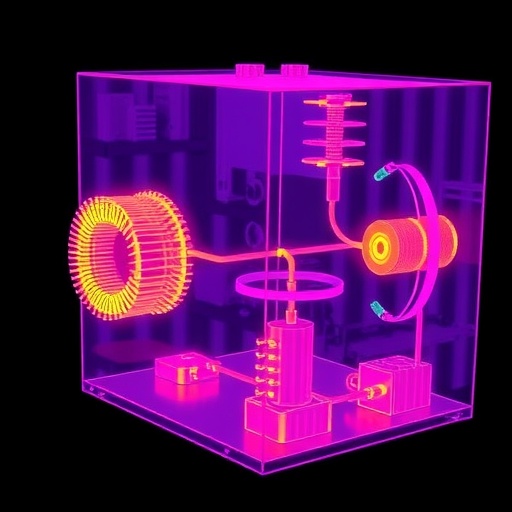

Leveraging the penetrating power of high-energy synchrotron X-rays coupled with an innovative serpentine scanning method, the multidisciplinary team successfully generated micrometer-resolution two-dimensional diffraction images. These images provide a cross-sectional view of the MEA components inside an operating CO₂ electrolyzer, a feat unattainable with conventional diagnostic tools. The direct visualization revealed that salt formation predominantly concentrates within the gas-flow channel regions of the gas diffusion electrode, rather than beneath the solid “land” areas that define the flow field plate. This spatial distinction challenges prior assumptions about uniform degradation and highlights the critical role of local transport phenomena.

Dr. Xu, leading the investigation, emphasized the transformational nature of this approach: “By visualizing the distribution of salts and their migration pathways, we have acquired a powerful diagnostic lens into the electrolyzer’s internal environment. This allows us to pinpoint specific zones vulnerable to salt-induced blockage, information crucial for refining materials and architectures to mitigate failure.” The revelation that salt accumulation is more severe in channel regions, where CO₂ transport is ostensibly more efficient, stems from the accelerated local generation of bicarbonate species fueled by enhanced gas supply through shorter diffusion pathways.

Professor Seger elaborated on this counterintuitive discovery, noting, “It was unexpected that areas with faster CO₂ access suffered more extensive salt buildup. Our analysis suggests that rapid CO₂ flux intensifies local electrochemical reactions, producing bicarbonate ions that precipitate as salts. This mechanism underscores the complex balance between optimal reactant delivery and the risk of accelerated degradation.” Understanding this nuanced interplay is key to breaking the performance-limiting feedback loop commonly observed in electrolyzers during prolonged operation.

Furthermore, the team’s analysis uncovered a notable migration pattern of salt deposits towards the junctions between the channel and land regions within the MEA. This migration is likely driven by convective effects induced by water vapor flux and gas bubble dynamics, leading to uneven spatial distribution of salt precipitation. Such heterogeneity in salt loading can cause localized hotspots of degradation, resulting in uneven current density and impairing overall device stability. By modeling these diffusion and migration pathways based on the extensive X-ray data, the researchers quantitatively demonstrated that the distinct transport lengths under channel and land areas critically influence salt accumulation patterns.

The implications of these findings extend well beyond CO₂ electrolyzers. The researchers posit that their two-dimensional in-operando X-ray diffraction imaging platform holds broad applicability across diverse electrochemical energy conversion and storage systems, including hydrogen fuel cells and water electrolyzers. As Dr. Jakub Drnec from ESRF highlighted, “Our technique provides a unique window into buried electrochemical interfaces, which are typically inaccessible to traditional probes. This opens avenues to study catalyst behavior, membrane integrity, and ion transport in real operational contexts, ultimately guiding accelerated development cycles for multiple clean energy technologies.”

Looking forward, the research consortium aims to augment their methodology by increasing temporal resolution, enabling sub-second imaging of transient processes within working devices. Such enhancements would facilitate the capturing of fast kinetics related to catalyst poisoning, electrolyte flooding, and gas bubble formation. Additionally, integrating multimodal synchrotron techniques could provide complementary chemical and structural insights, enriching the diagnostic matrix available for performance optimization. This multi-pronged approach aspires to deliver robust design principles that will underpin industrial-scale electrolyzers capable of sustainable and cost-effective conversion of CO₂ into value-added fuels and chemicals.

In conclusion, the advent of this innovative 2D X-ray diffraction imaging technique represents a paradigm shift in understanding the spatially complex phenomena governing CO₂ electrolyzer operation. By transcending the limitations of bulk-average measurements, this research unravels the microenvironmental heterogeneity responsible for salt-induced degradation, supplying an informed foundation for materials scientists and engineers to craft resilient and efficient electrochemical devices. As the global community intensifies efforts to decarbonize industry and energy sectors, such pioneering diagnostic capabilities will be instrumental in translating laboratory-scale advances into industrial realities, advancing the global agenda toward carbon-neutral energy systems.

Subject of Research: Real-time two-dimensional X-ray diffraction imaging of membrane-electrode assemblies in CO₂ electrolyzers revealing spatially resolved salt formation and transport.

Article Title: 2D X-ray Imaging Technique Reveals Hidden Processes in CO2 Electrolyzers

News Publication Date: 9-Sep-2025

Web References: https://doi.org/10.26599/CF.2025.9200053

Image Credits: Carbon Future, Tsinghua University Press

Keywords

CO2 electrolysis, in-operando imaging, X-ray diffraction, salt precipitation, membrane-electrode assembly, gas diffusion electrode, synchrotron radiation, electrochemical diagnostics, catalyst degradation, bicarbonate formation, gas transport pathways, electrolyzer stability