The quest for sustainable energy solutions has thrust lithium, a critical component in rechargeable batteries, into the global spotlight. As electric vehicles surge in popularity and renewable energy systems proliferate, the demand for lithium has escalated at an unprecedented pace. Traditionally sourced through evaporation ponds from salt flats and mineral ores, lithium extraction has encountered significant environmental and efficiency challenges. However, innovative membrane and electrochemical technologies are emerging as transformative tools to revolutionize how lithium is separated and recovered directly from complex brine sources, promising a new era of sustainable and efficient lithium production.

Lithium-rich brines exist in a variety of geological environments, including salt flats known as salars, oilfield brines, and geothermal brines. These aqueous solutions are characterized by highly variable compositions, containing not only lithium but also significant amounts of sodium, magnesium, calcium, potassium, and other minerals. This chemical diversity complicates lithium recovery efforts, necessitating highly selective methods capable of isolating lithium ions amid a crowded ionic milieu. Conventional evaporation-based lithium extraction, while cost-effective, is slow, water-intensive, and limited in its geographical applicability, underscoring the imperative for advanced separation techniques.

Direct lithium extraction (DLE) technologies have swiftly gained momentum as attractive alternatives to traditional processing. Central to these novel approaches are membrane and electrochemical processes that facilitate ion-selective transport and separation under controlled conditions. These methods offer the potential to drastically reduce processing times, lower water consumption, and avoid the expansive land footprints associated with evaporation ponds. By focusing on the physicochemical properties of lithium ions and exploiting selective membranes and electrical fields, DLE offers a pathway toward scalable and environmentally benign lithium recovery.

Nanofiltration membranes represent a class of size- and charge-selective barriers that can discriminate lithium ions from larger, multivalent ions abundant in brines. Operating under pressure-driven flow, these membranes leverage subtle differences in ionic radius and hydration shell characteristics to permit lithium passage while rejecting interfering species like magnesium and calcium. Despite their promise, nanofiltration membranes must overcome challenges such as membrane fouling, permeability-selectivity trade-offs, and durability in harsh saline environments to realize widespread industrial adoption.

Another promising electrochemical technique is electrosorption, where electric fields induce the adsorption of lithium ions onto charged electrode surfaces. This method harnesses the principles of capacitive deionization but requires the design of highly selective electrodes capable of preferentially binding lithium. Advances in electrode materials, such as the incorporation of lithium-ion sieving compounds or tailored nanostructured carbons, have enabled significant strides in lithium selectivity and adsorption capacity. Electrosorption offers the advantage of regenerability and energy-efficient operation but demands further optimization to enhance throughput and electrode longevity.

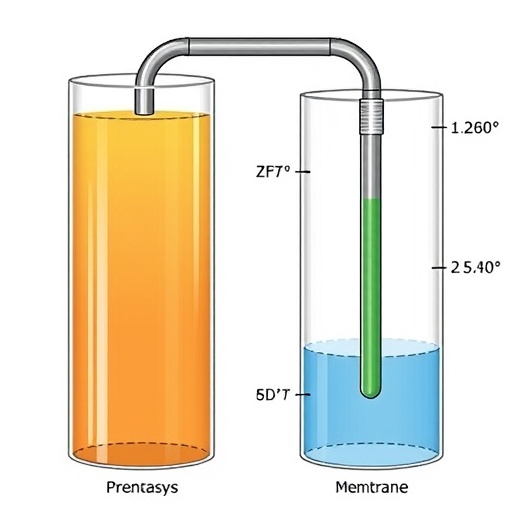

Electrodialysis leverages ion-exchange membranes and an applied electric potential to drive targeted ion migration across selective membranes. In lithium extraction, specialized membranes that exhibit high permeability for lithium ions while rejecting competing ions are essential. The integration of monovalent-selective ion-exchange membranes within electrodialysis stacks can facilitate the separation of lithium from multivalent ions, enhancing purity and recovery rates. Advances in membrane fabrication, including the control of charge density and nanoscale architecture, have improved separation performance, although scale-up and cost remain critical considerations.

The performance of membrane and electrochemical DLE technologies is intrinsically linked to several key factors, including brine composition, operating parameters, and material properties. High magnesium-to-lithium ratios, common in many brines, represent a significant hurdle due to magnesium’s similar ionic size and charge density. Moreover, the presence of organic matter and suspended solids can exacerbate membrane fouling and electrode degradation. Fine-tuning process parameters such as pH, temperature, applied voltage, and flow rates offers pathways to maximize lithium selectivity and minimize energy consumption.

From a materials engineering perspective, the development of robust, selective membranes and electrodes stands at the forefront of enabling next-generation DLE technologies. Innovations in polymer chemistry have yielded membranes with enhanced chemical stability and ion-selectivity, tailored through functional group modifications and nanocomposite incorporation. Likewise, electrode architectures optimized for high surface area, electrical conductivity, and selective ion affinity have demonstrated improved electrosorption capacities. Continued interdisciplinary research linking material science, electrochemistry, and process engineering is vital for overcoming existing limitations.

Environmental sustainability considerations underscore the importance of adopting membrane and electrochemical DLE technologies. Unlike evaporation-based methods, these approaches significantly reduce water usage and minimize surface disturbance, preserving local ecosystems. Additionally, their modular nature allows for deployment in geographically diverse areas, including oilfield and geothermal brines that were previously underexploited. By facilitating decentralized lithium production closer to consumption hubs, DLE processes also have the potential to reduce supply chain vulnerabilities and associated carbon footprints.

Scale-up of membrane and electrochemical lithium extraction processes demands a holistic understanding of system integration within the broader lithium recovery train. Pre-treatment steps to remove suspended solids and organics, post-treatment purification, and lithium concentration processes must be synergistically combined to achieve economically viable operation. Real-time process monitoring and control strategies informed by advanced sensors and data analytics can optimize these integrated treatment trains, ensuring consistent product quality and enhancing operational resilience.

Economic viability hinges on balancing capital expenditure with operational costs and product value. Although membrane and electrochemical units may require higher upfront investment compared to traditional evaporation ponds, their faster processing times and improved selectivity can lead to lower life-cycle costs. Furthermore, the ability to target lithium-rich brines with challenging chemistries elevates the resource base accessible to industry players. Demonstration projects and pilot plants currently underway will provide critical insights into techno-economic performance and inform pathways for commercialization.

Research frontiers in membrane and electrochemical lithium extraction continue to evolve rapidly, with emerging techniques such as hybrid membranes combining adsorption and ion exchange properties, and advanced redox-active materials for selective lithium capture. The integration of renewable electricity sources with electrosorption and electrodialysis operations can further decarbonize the extraction process. Additionally, machine learning-guided material design and process optimization hold promise for accelerating discovery and deployment of innovative solutions.

Policy and regulatory frameworks will also shape the trajectory of direct lithium extraction technologies. Governments and industry stakeholders are increasingly aware of the environmental and social implications of conventional lithium mining practices, which has spurred funding and support for cleaner alternatives. Establishing standards for environmental impact assessment, process emissions, and resource management will be instrumental in ensuring that novel technologies align with sustainability goals and community expectations.

As global energy landscapes pivot towards electrification and renewable integration, securing sustainable and resilient lithium supplies is paramount. Membrane and electrochemical separations for direct lithium extraction offer a compelling strategy to meet this demand while addressing environmental and operational challenges. The convergence of material innovation, process engineering, and system integration could unlock new lithium resources and transform supply chains, ultimately accelerating the transition to a cleaner, electrified future.

Looking ahead, the collaborative efforts spanning academia, industry, and policy arenas will catalyze the maturation of these technologies. Pilot-scale demonstrations and techno-economic assessments will validate their practical viability and environmental benefits. Moreover, the lessons learned in lithium brine extraction could extend to other critical mineral separations, broadening the impact of these advanced separation technologies. The synergy between scientific innovation and sustainability imperatives positions direct lithium extraction as a cornerstone of the global clean energy revolution.

In summary, the evolution of membrane and electrochemical methodologies for direct lithium extraction represents a paradigm shift in resource recovery. By surmounting the limitations of traditional processing and embracing selective, efficient separation mechanisms, these innovations can enhance the sustainability, scalability, and economic feasibility of lithium production. As the energy transition accelerates, such advancements will be essential to underpinning the battery technologies central to electrified transportation and renewable energy storage.

Subject of Research:

Direct lithium extraction using membrane and electrochemical separation technologies from diverse lithium brine sources.

Article Title:

Membrane and electrochemical separations for direct lithium extraction.

Article References:

Xu, L., Zhao, B., Zhang, X. et al. Membrane and electrochemical separations for direct lithium extraction. Nat Chem Eng (2025). https://doi.org/10.1038/s44286-025-00250-6

Image Credits: AI Generated