In a remarkable leap forward for materials science and aerospace engineering, researchers at Texas A&M University have discovered unprecedented properties in an innovative ultra-durable, recyclable smart plastic known as Aromatic Thermosetting Copolyester (ATSP). This groundbreaking material harbors not just extraordinary strength and resilience but possesses intrinsic adaptive capabilities, heralding a new era in the design and engineering of future composites for critical industries such as defense, aerospace, and automotive manufacturing. The findings, backed by extensive research funded by the U.S. Department of Defense and published in leading journals including Macromolecules and the Journal of Composite Materials, showcase the transformative potential of ATSP to redefine durability and sustainability in high-performance applications.

The study, led by Dr. Mohammad Naraghi, director of the Nanostructured Materials Lab and a professor of aerospace engineering at Texas A&M University, alongside Dr. Andreas Polycarpou at The University of Tulsa, reveals that ATSP transcends traditional material limitations by exhibiting capacities for on-demand self-healing and shape recovery. Unlike conventional plastics, whose mechanical integrity diminishes with damage, this advanced carbon-fiber reinforced composite demonstrates the ability to autonomously repair micro-cracks and restore its original form under appropriate thermal conditions. This capability is not only critical for extending the lifespan and safety of structural components but also promises to drastically lower maintenance costs and environmental impact through recyclability.

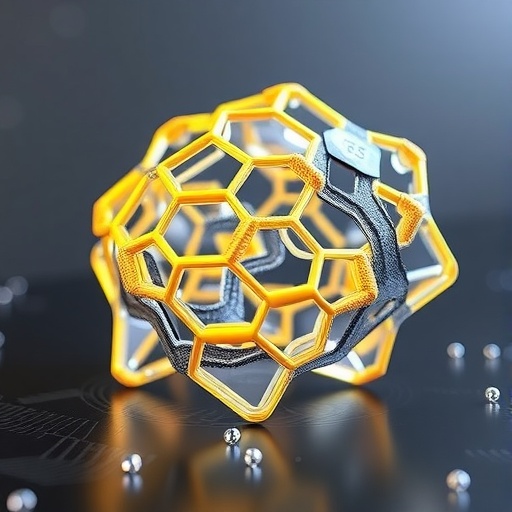

The exceptional functionalities of ATSP stem from its unique polymer chemistry classified among vitrimers—a novel class of materials characterized by dynamic covalent bond exchange. These reversible chemical bonds endow the polymer with thermoset-like rigidity and chemical stability, yet allow molecular rearrangement akin to thermoplastics when exposed to specific temperatures. This dual nature allows the composite to maintain high strength and durability during service while enabling adaptive healing or reprocessing when desired. When reinforced with discontinuous carbon fibers, ATSP achieves mechanical performance metrics that surpass those of traditional metals, being several times stronger than steel and lighter than aluminum, making it a standout candidate for aerospace structural components.

Central to the functionality of ATSP is its thermally activated bond exchange mechanism. During cyclical loading tests, the material was subjected to repeated tensile stress to mimic operational strains experienced in real-world aerospace and automotive environments. Researchers identified two critical thermal thresholds integral to ATSP’s behavior: the glass transition temperature (Tg), which defines the onset of polymer chain mobility, and a higher vitrification temperature, at which bond exchange reactions accelerate dramatically to facilitate self-healing and shape memory effects. By precisely controlling the exposure to these temperatures during testing, the team demonstrated the material’s ability to recover from deformation and damage, regaining mechanical strength through repeated cycles without structural degradation.

The implications of this study are profound for the aerospace sector, where materials must withstand extreme operational stresses and environmental temperatures. According to Dr. Naraghi, ATSP’s self-healing properties could revolutionize aircraft maintenance by enabling components to autonomously mend damage incurred during flight or ground operations. This would not only enhance safety by preventing crack propagation and catastrophic failure but also reduce downtime and hefty repair expenses. Moreover, the shape recovery aspect of ATSP provides a built-in material intelligence, allowing components to retain their designed geometries and performance profiles after deformation events, an innovation that pushes the boundaries of current composite technology.

Beyond aerospace, the automotive industry stands to gain significantly from ATSP’s capabilities. The material’s ability to recover from post-collision deformations presents an opportunity to improve vehicle crashworthiness and occupant protection. Upon impact, ATSP-reinforced composites could potentially absorb and then heal structural damages swiftly, maintaining the integrity of passenger compartments and critical safety systems. In this context, the inherent recyclability of ATSP also addresses growing environmental concerns by offering a durable plastic alternative that can be reshaped and reused multiple times without compromising mechanical properties, thereby supporting circular economy principles in transportation manufacturing sectors.

Methodologically, the research employed innovative cyclical creep testing and deep-cycle bending fatigue experiments, applying repeated mechanical stresses interspersed with high-temperature healing phases. Remarkably, after hundreds of such stress-healing cycles, the material not only avoided failure but exhibited an increase in durability, echoing biological processes such as skin’s stretch-heal-memory behavior. High-resolution imaging and microstructural analyses confirmed that the material after damage and healing closely resembled its pristine form, although minor wear and defects accumulated over multiple cycles were noted. Nevertheless, the chemical stability of the polymer matrix remained intact, indicating robust resistance to thermal degradation even at elevated temperatures reaching 280 degrees Celsius.

This combination of mechanical resilience, adaptive functionality, and environmental sustainability situates ATSP as a pioneering material platform for next-generation composites. The involvement of strategic partnerships, including support from the Air Force Office of Scientific Research (AFOSR) and collaboration with industry innovator ATSP Innovations, further underscores the commitment to translating fundamental scientific breakthroughs into tangible applications that advance national defense and commercial priorities. Dr. Naraghi highlights that these collaborations provide not only financial backing but critical multidisciplinary expertise and guidance, fostering agility in problem-solving and accelerating the path from laboratory discovery to field deployment.

As the research progresses, key challenges remain in scaling up ATSP production and integrating its unique properties reliably into complex engineering systems. However, the demonstrated ability to repeatedly heal and recover while sustaining ultra-high strength opens diverse possibilities in structural health monitoring and smart material design. Prospective applications range from resilient aerospace components and automotive safety systems to recyclable consumer products that adapt and extend their service life dynamically, reducing environmental footprints and costs. The evolution of smart plastics like ATSP marks a paradigm shift, where materials no longer passively endure damage but actively respond and adapt, embodying a new frontier in material innovation.

Dr. Naraghi credits the success of this research to the painstaking efforts of his students and postdoctoral researchers, emphasizing that rigorous trial and error, alongside vibrant academic and industrial collaborations, fueled the material’s development. The emerging blueprint provided by this study illustrates how bold scientific inquiry, strategic partnerships, and innovative materials chemistry converge to redefine what plastics can achieve—transforming them from static constructs into intelligent, evolving components that meet the escalating demands of modern engineering environments. With continued exploration and optimization, ATSP and related vitrimer-based composites are poised to disrupt how industries approach durability, sustainability, and adaptive functionality in their materials portfolio.

For more information about Dr. Mohammad Naraghi and his research, visit his faculty page at Texas A&M University’s Aerospace Engineering department.

Subject of Research: Ultra-durable, recyclable, and self-healing vitrimer carbon-fiber reinforced polymer composites (Aromatic Thermosetting Copolyester – ATSP)

Article Title: Identifying the origin of intrinsic self-healing gradual decay in vitrimer carbon fiber reinforced polymer composites

News Publication Date: 18-Jul-2025

Web References:

Image Credits: Dr. Mohammad Naraghi/Texas A&M University College of Engineering

Keywords

Plastics, Shape memory polymers, Aerospace engineering, Scientific journals, High resolution imaging, Materials processing, Reinforced plastics, Fabrication, Chemical elements, Aircraft, Automobile design, Engineering, Composite materials, Recycling, Waste management, Deformation, Shape memory, Steel, Materials science, Material properties