In the relentless pursuit of sustainable solutions to the environmental challenges posed by nuclear industry waste, a groundbreaking development in uranium remediation technology has emerged. Uranium contamination in wastewater is a pressing global concern, threatening ecosystems and human health due to its radiotoxicity and chemical toxicity. Traditional approaches to uranium recovery and removal, though effective to some extent, are hindered by slow adsorption kinetics or the limitations inherent in electrochemical methods. A recent breakthrough reported by Chen, Wang, Zheng, and colleagues introduces an innovative electron-buffering rechargeable microelectrode system that promises not only to overcome these bottlenecks but also to revolutionize the efficiency and scalability of uranium extraction from contaminated waters.

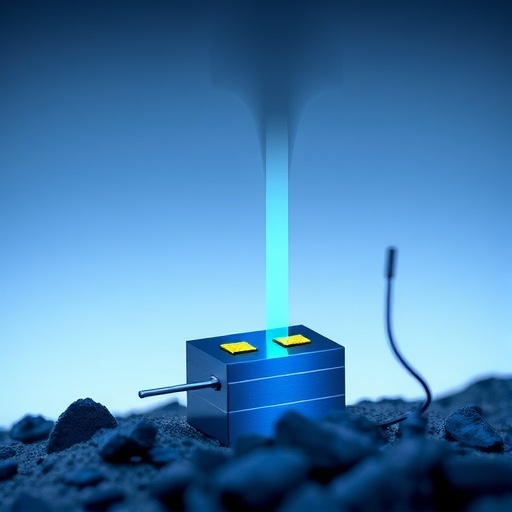

The novel system distinguishes itself by its elegant design which dissociates the processes of electron injection and uranium ion reduction, a coupling that has long restricted conventional electrochemical remediation techniques. Typically, direct electron injection into the bulk solution leads to the formation of insulating layers that block ion transport, consequently throttling the remediation rate. In contrast, the newly developed microelectrode adsorbent stores electrons electrochemically in a segregated step separate from uranium extraction. This temporal and spatial decoupling is a strategic innovation that enables uninterrupted uranium capture without the detrimental effects of surface passivation.

Fundamentally, the microelectrode operates through a three-step cyclical process: electron storage, uranium extraction, and adsorbent regeneration. During electron storage, electrons are housed within the microelectrode’s conductive matrix, effectively buffering charge without letting it interact prematurely with the aqueous environment, which might contain various competing ions. This electron reservoir can then be strategically deployed during the uranium extraction phase, releasing electrons in a controlled fashion that facilitates the selective reduction of uranyl ions bound on the electrode surface. This control circumvents the typical ion-blocking phenomena by avoiding the direct injection of electrons into the bulk solution and instead promotes surface-based redox transformation.

Crucial to the system’s efficacy is the presence of Fe–O bonds on the microelectrode surface that act as active sites for uranyl ion adsorption. These sites not only capture uranium species from the wastewater but also modulate the electrochemical environment to substantially lower the overpotential necessary for uranium reduction. In effect, this reduces the energy threshold for uranium ion conversion, allowing for faster kinetics and higher selectivity. Simultaneously, the adsorption process induces the release of charge-balancing cations from the microelectrode, which maintains a negatively charged surface that favors efficient mass transfer and continuous ion uptake.

Remarkably, this integrated mechanism translates into extraordinary performance metrics. The system achieves an initial uranium extraction rate of 1,062 milligrams per gram per hour (mg g⁻¹ h⁻¹), which stands among the highest reported for metal ion adsorption and electrochemical recovery devices. Furthermore, it boasts a uranium capacity of 854 mg g⁻¹, illustrating the material’s exceptional loading potential. These parameters are paired with an almost perfect electron utilization efficiency approaching 100%, indicating that nearly all electrons stored and released during the cycle contribute directly to uranium extraction without substantial parasitic losses.

Such performance is not limited to controlled laboratory conditions. When deployed for actual uranium mine wastewater, containing a complex mixture of dissolved elements and 0.545 parts per million (ppm) of uranium, the microelectrode system achieves an outstanding extraction efficiency of 97.1% within just six hours. The uranium capacity under these practical conditions reached 78.5 mg g⁻¹, validating the technology’s robustness and practical viability for environmental remediation applications beyond theoretical or idealized settings.

The design principles behind this microelectrode system are notable for their innovation in electrochemical engineering. Separating electron storage from chemical reduction allows for modularity and adaptability. The rechargeable nature of the adsorbent suggests potential for extensive reuse cycles, which is a compelling advantage in cost and sustainability terms. Unlike batch adsorption materials that saturate quickly and require regeneration steps involving harsh chemicals, this device facilitates clean regeneration via controlled electrochemical processes, reducing secondary waste and operational complexity.

By addressing the chronic challenge of ion-blocking layers that plague most electrochemical approaches, this technology opens new vistas for efficient and scalable uranium remediation. The electron-buffering strategy may be adapted or inspire similar designs for other problematic contaminants, broadening its environmental impact. Additionally, the fundamental materials design focusing on Fe–O active sites highlights the importance of surface chemistry engineering in synergizing adsorption and redox transformation processes, a principle that could guide further advancements in water purification technologies.

Beyond the immediate nuclear wastewater context, the environmental and economic implications of this work are substantial. Recovering uranium not only mitigates one of the most hazardous pollutants but also recovers a valuable resource that can be reused as nuclear fuel, contributing to a circular economy in the energy sector. Technologies capable of rapid, high-capacity, and efficient extraction of uranium from diluted streams can transform mining site management, reduce the footprint of legacy nuclear sites, and increase safety in vulnerable ecological zones.

The charge-balancing mechanism observed in the microelectrode system—where release of cations accompanies electron delivery—reveals an often overlooked but critical aspect of electrochemical remediation: maintaining electroneutrality to sustain mass transfer dynamics. This insight deepens our understanding of ion transport phenomena in electrode materials and underscores the potential benefits of careful tuning of the electrode surface’s ionic environment to optimize remediation processes.

Looking forward, the scalability of such electron-buffering microelectrode systems will be a crucial metric to monitor. Although initial lab-scale and field tests demonstrate promising outcomes, the translation to large flow-through reactors or in situ remediation setups will require engineering refinements, including optimization of electrode architecture, stability under prolonged operational stress, and integration with existing wastewater treatment infrastructure.

Moreover, exploring the compatibility of this system with other contaminants, particularly co-existing metal ions and organic species frequently found in uranium mine wastewater, will be essential to assess its selectivity and robustness. Understanding how competing adsorption or redox reactions influence the system’s performance could guide adaptations that tailor the technology for diverse remediation scenarios globally.

In the realm of sustainable environmental technology, innovations that bring together electrochemistry, materials science, and environmental engineering hold the key to addressing some of the most persistent and complex challenges. The electron-buffering rechargeable microelectrode adsorbent developed by Chen and colleagues exemplifies such synergy, marrying fundamental scientific insights with practical engineering solutions to deliver a powerful tool for nuclear industry wastewater management.

As global attention increasingly focuses on clean and safe water resources amidst accelerating industrialization, advances like these offer a beacon of hope. By leveraging sophisticated charge and ion management strategies, researchers are not only tackling contamination problems of the present but also paving the way for resilient and environmentally harmonious nuclear technologies of the future.

The study stands as a testament to the power of interdisciplinary research and the enduring promise of electrochemical technologies tailored for environmental sustainability. With further development, scale-up, and commercialization, electron-buffering microelectrode systems may become a mainstay in the global arsenal against uranium pollution, turning a daunting environmental challenge into an opportunity for resource recovery and ecological protection.

Subject of Research: Uranium remediation from nuclear wastewater using advanced electrochemical microelectrode adsorbents.

Article Title: Electron-buffering rechargeable microelectrode adsorbents for rapid environmental remediation of uranium-containing wastewater.

Article References:

Chen, S., Wang, X., Zheng, H. et al. Electron-buffering rechargeable microelectrode adsorbents for rapid environmental remediation of uranium-containing wastewater. Nat Water (2025). https://doi.org/10.1038/s44221-025-00471-2

Image Credits: AI Generated