While 3D printing has exploded in popularity, many of the plastic materials these printers use to create objects cannot be easily recycled. While new sustainable materials are emerging for use in 3D printing, they remain difficult to adopt because 3D printer settings need to be adjusted for each material, a process generally done by hand.

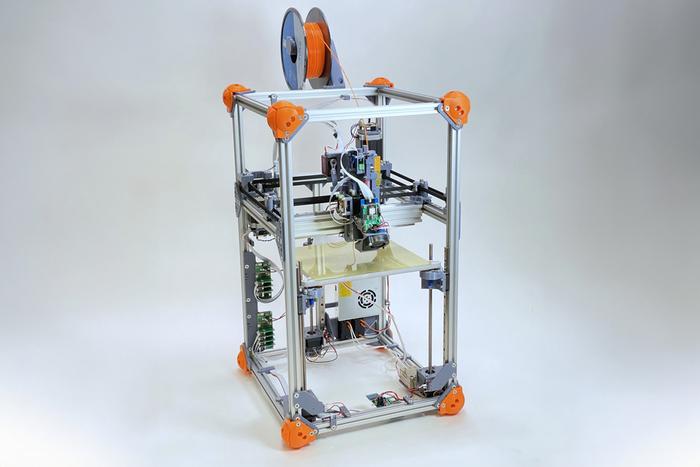

Credit: Courtesy of Neil Gershenfeld, Jake Read, et al

While 3D printing has exploded in popularity, many of the plastic materials these printers use to create objects cannot be easily recycled. While new sustainable materials are emerging for use in 3D printing, they remain difficult to adopt because 3D printer settings need to be adjusted for each material, a process generally done by hand.

To print a new material from scratch, one must typically set up to 100 parameters in software that controls how the printer will extrude the material as it fabricates an object. Commonly used materials, like mass-manufactured polymers, have established sets of parameters that were perfected through tedious, trial-and-error processes.

But the properties of renewable and recyclable materials can fluctuate widely based on their composition, so fixed parameter sets are nearly impossible to create. In this case, users must come up with all these parameters by hand.

Researchers tackled this problem by developing a 3D printer that can automatically identify the parameters of an unknown material on its own.

A collaborative team from MIT’s Center for Bits and Atoms (CBA), the U.S. National Institute of Standards and Technology (NIST), and the National Center for Scientific Research in Greece (Demokritos) modified the extruder, the “heart” of a 3D printer, so it can measure the forces and flow of a material.

These data, gathered through a 20-minute test, are fed into a mathematical function that is used to automatically generate printing parameters. These parameters can be entered into off-the-shelf 3D printing software and used to print with a never-before-seen material.

The automatically generated parameters can replace about half of the parameters that typically must be tuned by hand. In a series of test prints with unique materials, including several renewable materials, the researchers showed that their method can consistently produce viable parameters.

This research could help to reduce the environmental impact of additive manufacturing, which typically relies on nonrecyclable polymers and resins derived from fossil fuels.

“In this paper, we demonstrate a method that can take all these interesting materials that are bio-based and made from various sustainable sources and show that the printer can figure out by itself how to print those materials. The goal is to make 3D printing more sustainable,” says senior author Neil Gershenfeld, who leads CBA.

His co-authors include first author Jake Read a graduate student in the CBA who led the printer development; Jonathan Seppala, a chemical engineer in the Materials Science and Engineering Division of NIST; Filippos Tourlomousis, a former CBA postdoc who now heads the Autonomous Science Lab at Demokritos; James Warren, who leads the Materials Genome Program at NIST; and Nicole Bakker, a research assistant at CBA. The research is published in the journal Integrating Materials and Manufacturing Innovation.

Shifting material properties

In fused filament fabrication (FFF), which is often used in rapid prototyping, molten polymers are extruded through a heated nozzle layer-by-layer to build a part. Software, called a slicer, provides instructions to the machine, but the slicer must be configured to work with a particular material.

Using renewable or recycled materials in an FFF 3D printer is especially challenging because there are so many variables that affect the material properties.

For instance, a bio-based polymer or resin might be composed of different mixes of plants based on the season. The properties of recycled materials also vary widely based on what is available to recycle.

“In ‘Back to the Future,’ there is a ‘Mr. Fusion’ blender where Doc just throws whatever he has into the blender and it works ]as a power source for the DeLorean time machine]. That is the same idea here. Ideally, with plastics recycling, you could just shred what you have and print with it. But, with current feed-forward systems, that won’t work because if your filament changes significantly during the print, everything would break,” Read says.

To overcome these challenges, the researchers developed a 3D printer and workflow to automatically identify viable process parameters for any unknown material.

They started with a 3D printer their lab had previously developed that can capture data and provide feedback as it operates. The researchers added three instruments to the machine’s extruder that take measurements which are used to calculate parameters.

A load cell measures the pressure being exerted on the printing filament, while a feed rate sensor measures the thickness of the filament and the actual rate at which it is being fed through the printer.

“This fusion of measurement, modeling, and manufacturing is at the heart of the collaboration between NIST and CBA, as we work develop what we’ve termed ‘computational metrology,’” says Warren.

These measurements can be used to calculate the two most important, yet difficult to determine, printing parameters: flow rate and temperature. Nearly half of all print settings in standard software are related to these two parameters.

Deriving a dataset

Once they had the new instruments in place, the researchers developed a 20-minute test that generates a series of temperature and pressure readings at different flow rates. Essentially, the test involves setting the print nozzle at its hottest temperature, flowing the material through at a fixed rate, and then turning the heater off.

“It was really difficult to figure out how to make that test work. Trying to find the limits of the extruder means that you are going to break the extruder pretty often while you are testing it. The notion of turning the heater off and just passively taking measurements was the ‘aha’ moment,” says Read.

These data are entered into a function that automatically generates real parameters for the material and machine configuration, based on relative temperature and pressure inputs. The user can then enter those parameters into 3D printing software and generate instructions for the printer.

In experiments with six different materials, several of which were bio-based, the method automatically generated viable parameters that consistently led to successful prints of a complex object.

Moving forward, the researchers plan to integrate this process with 3D printing software so parameters don’t need to be entered manually. In addition, they want to enhance their workflow by incorporating a thermodynamic model of the hot end, which is the part of the printer that melts the filament.

This collaboration is now more broadly developing computational metrology, in which the output of a measurement is a predictive model rather than just a parameter. The researchers will be applying this in other areas of advanced manufacturing, as well as in expanding access to metrology.

This research is supported, in part, by the National Institute of Standards and Technology and the Center for Bits and Atoms Consortia.

###

Written by Adam Zewe, MIT News

Paper: “Online Measurement for Parameter Discovery in Fused Filament Fabrication”

Journal

Integrating Materials and Manufacturing Innovation

Article Title

“Online Measurement for Parameter Discovery in Fused Filament Fabrication”