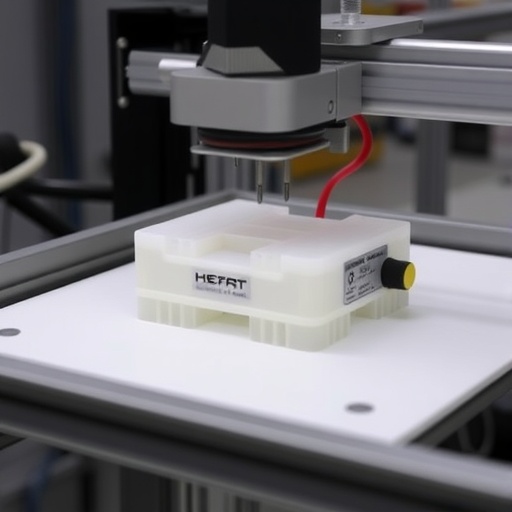

In a groundbreaking advancement poised to revolutionize manufacturing as we know it, researchers at the Massachusetts Institute of Technology (MIT) have unveiled a pioneering 3D-printing platform capable of fabricating intricate electronic devices in mere hours. This innovative system, adept at processing multiple functional materials, facilitates the complete 3D printing of complex electric machines — including electric linear motors — in a streamlined single-step process, marking a significant departure from the traditionally fragmented, multistage manufacturing methodologies.

At the heart of this breakthrough lies a sophisticated extrusion-based 3D printer, surgically engineered with four distinct extrusion tools, each optimized to handle disparate printable materials simultaneously. Unlike conventional multimaterial extrusion printers limited to switching between one or two materials of similar physical form, this platform deftly manages a diversity of material forms including filament, pellet, and ink-like substances. This capability is particularly crucial for integrating electrically conductive materials alongside hard magnetic compounds within a singular printed piece, enabling enhanced functional integration.

The researchers tackled formidable engineering challenges inherent to synchronizing materially and mechanically heterogeneous extrusion methods within one cohesive instrument. Electromechanical elements such as robotic arms and nozzles operate in concert under a novel control framework incorporating strategically positioned sensors. This ensures impeccable precision in nozzle alignment and layer deposition, a vital factor considering the microscopic tolerances required for efficient electric motor performance. Even minuscule misalignments could critically undermine the functionality of the final device.

One of the most remarkable demonstrations of this technology is the successful fabrication of a fully functional electric linear motor, produced from five different materials in approximately three hours. Unlike traditional motor manufacturing — often reliant on complex assembly and extensive post-processing — this printed motor required only a single post-fabrication magnetization to achieve full operational capacity. The researchers report that material costs for these motors remain astoundingly low, roughly 50 cents per unit, potentially democratizing production economics significantly.

Beyond cost efficiency, the performance metrics of the 3D-printed motor are compelling. Its actuation capabilities outperform common linear engines which conventionally employ complicated hydraulic amplification systems, showcasing how additive manufacturing can transcend merely replicating existing technologies to actually exceeding their functional benchmarks. The potential implications for industries reliant on precise linear motion — such as robotics, optical systems, and logistics — are profound.

Integral to achieving such multifunctionality was the meticulous engineering of each extruder nozzle to suit material-specific processing constraints. Electrically conductive inks, prized for conductivity but sensitive to heat and UV exposure, necessitated extrusion via a gentle pressure-driven system rather than conventional thermal extrusion. Conversely, magnetic materials and structural components were extruded using thermally driven processes, all orchestrated seamlessly to fabricate a monolithic device with layered complexity.

This multimaterial compatibility unlocks far-reaching possibilities not only for electric motors but for a vast spectrum of electronic components, potentially enabling onsite fabrication of customized, highly integrated devices across sectors from automotive and aerospace to medical equipment. By condensing fabrication into a single, automated process, the platform could drastically reduce manufacturing lead times, supply chain dependencies, and material waste — heralding a new paradigm in sustainable production.

Looking forward, the MIT team envisions enhancements to their platform that could fully automate subsequent magnetization steps, integrate additional tooling for broader material compatibility, and extend capabilities to rotary electric motors. These developments would edge additive manufacturing closer to producing complete, commercial-grade electromechanical systems in a single batch, further transforming how hardware is conceived, designed, and deployed.

Luis Fernando Velásquez-García, principal research scientist and senior author of the study, remarks on the transformative potential of this technology: “This is not just a technical achievement but a foundational shift in manufacturing. We envision a future where complex hardware is fabricated onsite in one step, disentangled from entrenched global supply chains.” Such a shift promises resilience and agility, crucial in a world increasingly vulnerable to supply disruptions.

The platform’s modular architecture with robotic arms precision-handing tool changes heralds a new class of adaptive manufacturing systems. Employing real-time feedback from embedded sensors, the machine achieves nanometer-scale alignment across layers, ensuring the electronic and magnetic pathways within the device are flawlessly integrated. This level of integration is essential for optimizing energy conversion and operational efficiency of electric machines.

Moreover, by leveraging additive manufacturing’s inherent material efficiency, the system minimizes waste associated with traditional subtractive methods. This aligns with broader industrial trends emphasizing eco-friendly practices while maintaining performance standards. The ability to rapidly prototype and iterate designs onsite further accelerates innovation cycles, empowering engineers to tailor devices to specific applications without costly manufacturing lead times.

The study detailing this technological leap was published in the journal Virtual and Physical Prototyping and represents a collaborative effort led by graduate students Jorge Cañada and Zoey Bigelow under Velásquez-García’s guidance at MIT’s Microsystems Technology Laboratories. The research received funding support from Empiriko Corporation and the La Caixa Foundation.

As the boundaries of what can be fabricated via 3D printing continue to expand, this multimaterial extrusion platform symbolizes a pivotal stride towards fully integrated, complex electromechanical systems created on demand. It holds the promise of reshaping sectors as diverse as manufacturing, transportation, healthcare, and beyond, with implications for cost, speed, customization, and sustainability — a veritable glimpse into the factory of the future.

Subject of Research: Development of a multimaterial 3D-printing platform for the fabrication of complex electric machines.

Article Title: Fully 3D-Printed electric motor manufactured via multi-modal, multi-material extrusion.

News Publication Date: February 16, 2026.

Web References: https://doi.org/10.1080/17452759.2026.2613185

References: Velásquez-García, L. F., Cañada, J., & Bigelow, Z. (2026). Fully 3D-Printed electric motor manufactured via multi-modal, multi-material extrusion. Virtual and Physical Prototyping.

Image Credits: MIT

Keywords: Applied sciences and engineering, Industrial science, Printing, Engineering, Electronics, Electrical engineering, Manufacturing