In the quest to mitigate the escalating climate crisis, scientists have pioneered a groundbreaking technique that promises to revolutionize carbon capture technology. This novel process harnesses the power of microwave radiation to rapidly synthesize nitrogen-doped ultramicroporous carbon materials derived from coal, delivering outstanding carbon dioxide adsorption capabilities while drastically reducing energy consumption and production time. Such advancements open new avenues for scalable, cost-effective carbon sequestration solutions critical for addressing global warming.

Traditional carbon capture methods, though effective, suffer from inherent limitations due to their reliance on prolonged high-temperature treatments. These conventional techniques often demand extended furnace heating durations—sometimes exceeding an hour—leading to excessive energy costs and partial degradation of functional groups critical for adsorption performance. The microwave-assisted synthesis method introduced by the research team represents a paradigm shift, employing volumetric heating to activate carbon precursors swiftly while preserving essential nitrogen and oxygen surface groups that significantly enhance CO₂ affinity.

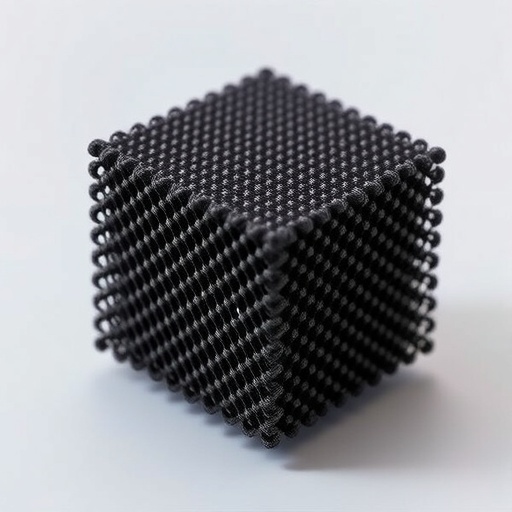

The core innovation lies in a combined approach incorporating a pre-oxidation treatment followed by microwave activation, applied to Ningdong coal as the feedstock material. This pre-oxidation step introduces oxygen-containing active sites within the coal matrix, facilitating efficient incorporation of nitrogen atoms during the subsequent microwave-driven activation. As a result, the end product is a nitrogen-enriched ultramicroporous carbon characterized by a high density of adsorption sites and finely tuned pore sizes measuring approximately 0.6 to 0.7 nanometers, dimensions that align precisely with the kinetic diameter of CO₂ molecules, optimizing selective adsorption.

Experimentally, the enhanced carbon material demonstrated remarkable CO₂ uptake capacities, reaching 4.72 millimoles per gram at 0°C and retaining a high adsorption capacity of 3.33 millimoles per gram at ambient room temperature. Apart from its impressive adsorption strength, the material exhibited pronounced selectivity in differentiating between carbon dioxide and nitrogen molecules, an essential trait for practical gas separation technologies aiming to capture CO₂ from flue gases or industrial emissions where nitrogen is the dominant background gas.

This revolutionary technique not only significantly improves adsorption performance but also addresses sustainability concerns related to traditional manufacturing processes. Microwave activation reduces the synthesis time to about ten minutes, a substantial decrease compared to hour-long furnace treatments, and leverages efficient microwave-to-thermal energy conversion, leading to an energy consumption reduction by almost two orders of magnitude. Such energy efficiency underscores the potential scalability and commercial viability of this approach, especially given the low-cost raw material of coal, which remains abundant globally.

Underlying these advancements are detailed insights into the synergistic relationship between surface chemistry and pore architecture that govern carbon capture efficiency. The nitrogen heteroatoms doped into the carbon framework enhance chemical interactions by increasing surface basicity, thereby promoting stronger binding of the polarizable CO₂ molecules. Concurrently, the ultramicropores impose molecular confinement, strengthening physical adsorption forces and preventing premature desorption, a dual mechanism that culminates in both high capacity and selectivity.

The strategic engineering of pore size distribution plays a pivotal role in optimizing adsorption kinetics, balancing rapid molecular diffusion with maximal surface contact. By focusing on ultramicropores within the 0.6–0.7 nm range, the researchers designed pores just large enough to accommodate CO₂ molecules but restrictive enough to exclude larger nitrogen molecules. This precise tailoring of pore geometry is a critical factor that distinguishes this carbon material as a superior candidate for real-world carbon capture applications.

Moreover, the method’s scalability is supported by the inherent advantages of microwave processing, which allows uniform volumetric heating and rapid thermal ramping. These attributes prevent structural collapse and maintain the integrity of the doped functional groups, challenges commonly faced during conventional high-temperature treatments. Consequently, this technique can be readily adapted for industrial production, accelerating the deployment of cost-effective carbon adsorbents at scale for power plants, manufacturing facilities, and other emission-intensive industries.

The implications of this research extend beyond mere carbon dioxide adsorption. The principles demonstrated here can inform the design of advanced porous carbon materials for a broad range of gas separation and storage applications, including methane capture, hydrogen purification, and even energy storage devices. The ability to finely control doping elements and pore dimensions using rapid microwave synthesis opens the door to multifunctional materials with tailor-made properties.

Furthermore, the environmental impact of this innovation is profound. By dramatically reducing the energy footprint associated with the production of carbon adsorbents and enabling efficient CO₂ capture, this approach contributes directly to the mitigation of greenhouse gas emissions. It supports the global transition toward carbon neutrality by facilitating affordable and effective sequestration technologies capable of integrating with existing industrial infrastructures while minimizing additional energy demand.

As global carbon capture demands escalate in response to climate policy targets and international agreements, advancements such as microwave-assisted nitrogen-doped ultramicroporous carbon materials will become indispensable. They represent a critical technology class that combines economic feasibility, scalability, and superior performance — attributes necessary to bridge the gap between laboratory research and industrial application.

In summary, the study presents a compelling case for redefining carbon adsorbent synthesis through innovative microwave-assisted methodologies, demonstrating that the convergence of surface chemistry, pore engineering, and sustainable processing technologies can produce materials poised to make a tangible impact on climate change mitigation efforts worldwide.

Subject of Research: Not applicable

Article Title: Rapid microwave synthesis of nitrogen-doped ultramicroporous coal-based carbon with enhanced CO2 adsorption performance

News Publication Date: 4-Feb-2026

Web References:

https://doi.org/10.48130/scm-0026-0001

References:

Feng Y, Meng X, Li J, Xue N, Li W, et al. 2026. Rapid microwave synthesis of nitrogen-doped ultramicroporous coal-based carbon with enhanced CO₂ adsorption performance. Sustainable Carbon Materials 2: e006.

Image Credits:

Yulin Feng, Xiaoxiao Meng, Jingyu Li, Naiyuan Xue, Wanjing Li, Miaoting Sun, Jiaxiang Chen, Xingxing Wang, Ruida Zhou, Wenjun Zhuang, Jihui Gao, Guangbo Zhao & Wei Zhou

Keywords:

Carbon, Black carbon, Microwave radiation, Nitrogen, Oxygen, Adsorption