In the rapidly evolving domain of advanced electronic packaging, the quest for reliable, durable, and thermally stable interconnects remains a paramount challenge. Recently, a groundbreaking study conducted by Hsu, Lin, Huang, and their colleagues has unveiled a novel approach to significantly enhance the thermal stability of low-temperature copper-copper (Cu-Cu) bonding. This advancement employs innovative metal passivation technology that promises to revolutionize the field, addressing longstanding issues related to device longevity and performance under thermal stress.

Copper has long been a material of choice for electronic interconnects due to its excellent electrical and thermal conductivity. However, low temperature Cu-Cu bonding processes have historically suffered from thermal instability, severely limiting their application, especially in cutting-edge microelectronics where device miniaturization and operational reliability are critical. The research team’s method offers a transformative solution that not only preserves the integrity of the bonds at elevated temperatures but does so without compromising the performance benefits intrinsic to copper.

The core challenge in low temperature Cu-Cu bonding lies in the susceptibility of the interface to degradation caused by oxidation and atomic diffusion during thermal cycling. Traditional approaches often require high bonding temperatures to form robust intermetallics, which can induce thermal damage to sensitive components. The metal passivation technology introduced here circumvents these issues by applying a protective layer that effectively inhibits oxidation while facilitating atomic adhesion at significantly lower temperatures.

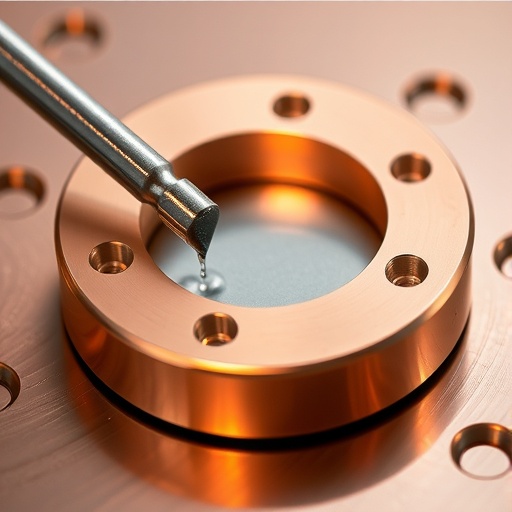

Through meticulous experimentation, the researchers detailed how their metal passivation layer—formed via precise chemical vapor deposition processes—acts as an ultra-thin barrier, preventing the formation of copper oxides that typically weaken the bonding interface. This protective coating allows the copper surfaces to remain pristine prior to and during bonding, which is crucial for establishing strong covalent-like bonds at temperatures far below those conventionally required.

Furthermore, the study elucidates the microstructural evolution of the Cu-Cu interface under thermal stress. Sophisticated microscopy and spectroscopy analyses demonstrated that the passivation technology not only suppresses oxide formation but also modulates atomic diffusion. This leads to a controlled interface morphology that enhances mechanical interlocking and electronic conduction pathways, thereby bolstering the bond’s thermal and electrical stability.

One of the most striking outcomes of this innovation is the dramatic improvement in bond reliability over extended thermal cycling tests. Devices fabricated with the passivation-enhanced Cu-Cu bonds exhibited minimal resistance changes and negligible interfacial degradation after prolonged exposure to temperatures exceeding typical operating ranges. This suggests a substantial leap forward in packaging resilience, enabling electronics to withstand harsh conditions without failure.

The implications of these findings are profound for industries reliant on advanced semiconductor packaging, such as consumer electronics, automotive systems, and aerospace technology. Enhanced thermal stability in Cu-Cu bonding reduces the risk of device failure due to thermal fatigue, potentially extending product lifespans and improving overall system reliability. This translates into cost savings and performance gains that could impact everything from smartphones to electric vehicles.

Additionally, the low temperature aspect of the bonding process aligns well with the trends towards energy-efficient manufacturing. By reducing the thermal budget required for bonding, this technology minimizes thermal stress on sensitive components, lowers energy consumption during fabrication, and enables integration of temperature-sensitive materials and substrates that were previously impractical.

Another notable advantage lies in the scalability and compatibility of the metal passivation technique. The process seamlessly integrates with existing manufacturing lines, requiring minimal changes to equipment and workflow. This aspect is critical for industry adoption, as it lowers barriers related to cost and complexity, accelerating the pathway from lab breakthrough to commercial implementation.

The research also delves into the fundamental bonding mechanisms facilitated by the passivated interface. Unlike conventional approaches that rely heavily on diffusion bonding or high-temperature annealing to achieve bond strength, the metal passivation layer promotes direct atomic contact and electron sharing at the interface. This subtle but significant mechanism preserves the intrinsic properties of copper while enhancing interface cohesion.

In the broader context of electronic packaging innovation, this development complements other advances such as wafer-level packaging and heterogeneous integration. By improving the reliability of Cu-Cu bonds at low temperatures, the technology supports the trend toward denser, more multifunctional devices, where thermal management and mechanical integrity are increasingly critical.

The study’s authors emphasize that future work will explore optimization of the passivation layer composition and thickness to further tailor performance characteristics to specific applications. They also foresee potential extensions of the technology to other metal-metal bonding systems, broadening its impact across various metallurgical interfaces in microelectronics and beyond.

From a scientific standpoint, this research bridges gaps between materials science, surface chemistry, and electronic device engineering. The interdisciplinary approach underscores the importance of precise surface engineering to resolve persistent challenges in microelectronic fabrication and highlights the potential for surface passivation strategies to unlock new performance regimes.

As the electronics industry continues its relentless push for miniaturization and higher operational speeds, materials and interface innovations like metal passivation for Cu-Cu bonding will be instrumental. Not only do they enhance device reliability, but they also open avenues for novel designs and applications that were previously unattainable due to thermal limitations.

This groundbreaking research by Hsu and colleagues undoubtedly marks a milestone in the evolution of electronic packaging. By offering a solution that simultaneously achieves low temperature bonding and exceptional thermal stability, the study sets a new standard for interconnect technology in high-performance electronic systems.

Looking ahead, the deployment of this technology in commercial products could catalyze a wave of innovation across multiple sectors, driving improvements in consumer electronics, medical devices, wireless communication, and even quantum computing architectures that demand unparalleled material performance.

In summary, the introduction of metal passivation technology for enhancing low temperature Cu-Cu bonding represents a significant technical leap. It addresses one of the most pressing challenges in advanced electronic packaging—thermal instability at the bonding interface—through a scientifically elegant and practically viable solution. The study’s comprehensive analysis and demonstrated results point to a future wherein electronic devices are not only more reliable but also manufactured with greater efficiency and versatility.

This pioneering work is poised to inspire a new generation of research and development focused on surface engineering and interface materials, ultimately shaping the next chapter of electronic device innovation in an increasingly connected and technologically dependent world.

Subject of Research: Thermal stability enhancement in low temperature copper-copper bonding via metal passivation technology for electronic packaging.

Article Title: Thermal stability enhancement of low temperature Cu-Cu bonding using metal passivation technology for advanced electronic packaging.

Article References:

Hsu, MP., Lin, TY., Huang, HJ. et al. Thermal stability enhancement of low temperature Cu-Cu bonding using metal passivation technology for advanced electronic packaging. Commun Eng (2025). https://doi.org/10.1038/s44172-025-00551-x

Image Credits: AI Generated