In the relentless pursuit of higher energy densities within all-solid-state lithium batteries (ASSBs), chloride solid electrolytes (CSEs) have emerged as compelling candidates due to their impressive ionic conductivity and robust chemical stability. However, a formidable obstacle persists: these electrolytes notoriously falter under ultrahigh voltage conditions, specifically beyond 4.5 volts, where oxidative decomposition severely curtails battery longevity and performance. Addressing this vexing challenge, groundbreaking research from Shenzhen University, spearheaded by Professors Guangliang Gary Liu and Wenjin Li, unveils a revolutionary approach featuring ferroelectric barium titanate (BaTiO₃, or BTO) nanoparticles. This innovation masterfully modulates interfacial electric fields, effectively stabilizing CSEs and enabling unprecedented high-voltage operation in ASSBs.

Ferroelectric materials like BaTiO₃ possess spontaneous electric polarization that can be switched by an external electric field. This intrinsic property of BTO is pivotal, as it equips the nanoparticle coating to counterbalance the intense electric fields at the cathode-electrolyte interface—a notorious locus for electrolyte degradation. By strategically harnessing BTO’s ferroelectric polarization, the research team has engineered a surface modification layer on Li₂.₅Y₀.₅Zr₀.₅Cl₆ (LYZC), a chloride-based solid electrolyte, that suppresses oxidative breakdown even at a daunting 4.8 V.

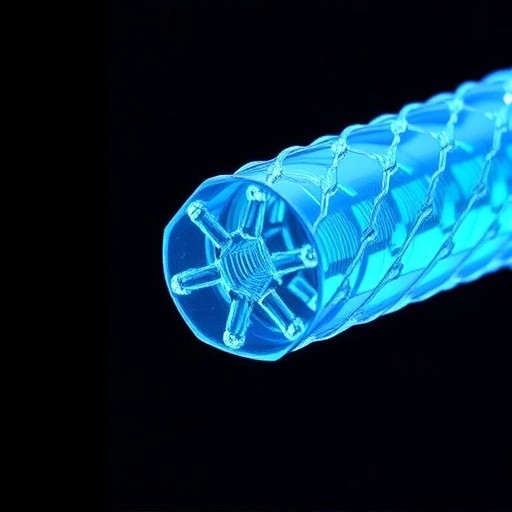

One of the most striking accomplishments of this work lies in the coating methodology itself. Utilizing a time-efficient ball milling process, BTO nanoparticles are uniformly deposited onto the LYZC particles, forming a core–shell architecture where the electrolyte is encapsulated within a nanometric BTO layer approximately 50 to 100 nanometers thick. Crucially, this intimate contact does not disrupt the bulk crystal structure of the chloride electrolyte, preserving its intrinsic properties. This seamless integration is a significant leap forward, proving that high-performance coatings can be scalably realized without sacrificing fundamental ionic transport pathways.

Preserving lithium-ion (Li⁺) conductivity in the electrolyte is essential for efficient battery operation. Despite BTO being ionically inactive, the coating remarkably maintains a high Li⁺ conductivity of approximately 1.06 mS cm⁻¹. Detailed solid-state nuclear magnetic resonance (NMR) studies illuminate an intriguing mechanism: Li⁺ ions experience enhanced mobility along the interfaces between BTO and LYZC, suggesting that the ferroelectric coating not only acts as a passive shield but also actively facilitates ion transport via surface-mediated diffusion channels.

The suppressive effect on parasitic interfacial reactions forms the bedrock for the enhanced stability observed in these batteries. Traditionally, chloride solid electrolytes suffer degradation pathways generating by-products such as ZrCl₃O and YCl₂O, which impair electrode-electrolyte compatibility and degrade cell efficiency. The BTO coating exquisitely minimizes the formation of these detrimental compounds, thereby preserving the structural and chemical integrity of the battery components and curtailing the cascade of capacity loss.

In tandem, the research delves into the cathode’s structural stability under aggressive cycling conditions. Single crystalline NCM811 (SCNCM811) is an advanced cathode material celebrated for its high capacity but vulnerable to irreversible phase transitions under high voltages, often translating to rock-salt phase formation that diminishes electrochemical performance. Through rigorous X-ray diffraction (XRD) and high-resolution transmission electron microscopy (HRTEM) analyses, the team demonstrates that the BTO-modified interface dramatically suppresses these phase transformations. This not only stabilizes the cathode’s layered structure but also enhances its compatibility with the solid electrolyte, a synergy critical for long-term cycle life.

Performance testing of all-solid-state cells assembled with the BTO-coated LYZC electrolyte yields impressive metrics: the batteries retain 76% of their initial capacity after 150 cycles at a demanding 0.5C rate and 4.8 V cutoff voltage. Even more compelling, the system exhibits superior rate capability, delivering 95.4 mAh g⁻¹ after 200 cycles at 1C, which nearly doubles the capacity retention compared to cells using pristine LYZC. These outcomes collectively showcase the transformative impact of interfacial electric field engineering via a ferroelectric nanoparticle platform.

Beyond technical prowess, the approach offers substantial advantages in scalability and cost-efficiency. Ball milling, being a widely accessible and industrially relevant technique, ensures that this coating process can be translated into mass manufacturing contexts without prohibitive expense or complexity. The ability to modulate interface electric fields through material engineering, rather than resorting to exotic or rare materials, promises to accelerate commercialization of next-generation ASSBs.

The implications of this research resonate beyond chloride electrolytes alone. Electric field optimization as a concept provides a fertile avenue for enhancing the interfacial chemistry not only in lithium-ion systems but potentially across other emerging battery chemistries that struggle with electrolyte degradation at high voltages. The ferroelectric BaTiO₃, in particular, may inspire analogous coatings tailored for different solid electrolyte classes, representing a versatile toolkit for battery interface science.

Future investigations may focus on further unraveling the precise dynamics of polarization switching in operation, the long-term stability of the BTO coating under diverse cycling regimes, and integration into full battery packs under practical conditions. Yet, the foundational discovery here marks a significant leap toward overcoming one of the most persistent barriers in ASSB technology—the unstable interface at ultrahigh voltages.

In conclusion, the Shenzhen University team’s innovation heralds a new paradigm in battery engineering. By marrying ferroelectric nanomaterials with chloride solid electrolytes, they have carved a pathway towards high-energy, durable, and safe lithium batteries capable of delivering stable performance well beyond the conventional voltage limits. This work exemplifies how fundamental materials science can be leveraged to tackle real-world energy storage challenges and paves the way for a future of electrification powered by robust, all-solid-state batteries.

The prospect of integrating such advances into commercial batteries is tantalizing, promising devices with prolonged life spans, enhanced safety margins, and higher energy output. As demands for electrified transportation, renewable energy storage, and portable electronics escalate, the impact of such material innovations reverberates across industries and societies. The confluence of advanced ferroelectric coatings and solid-state electrolyte design thus stands poised to redefine the landscape of energy storage technology.

This breakthrough invites the broader scientific and engineering communities to rethink electrolyte interfaces with an electric field lens, moving beyond conventional chemical passivation strategies. Ferroelectric nanoparticles, once confined to niche applications, now emerge as linchpins in the quest for resilient, high-voltage battery interfaces. As this research progresses from laboratory demonstrations toward real-world implementations, a new chapter unfolds in electrochemical energy storage innovation.

Subject of Research: Experimental study on surface modification of chloride solid electrolytes using ferroelectric BaTiO₃ nanoparticles to enhance high-voltage stability in all-solid-state lithium batteries.

Article Title: BaTiO3 Nanoparticle‑Induced Interfacial Electric Field Optimization in Chloride Solid Electrolytes for 4.8 V All‑Solid‑State Lithium Batteries

News Publication Date: 1-Sep-2025

Web References: DOI: 10.1007/s40820-025-01901-2

Image Credits: Qingmei Xiao, Shiming Huang, Donghao Liang, Cheng Liu, Ruonan Zhang, Wenjin Li, Guangliang Gary Liu

Keywords

Electrolytes, All-solid-state batteries, Ferroelectric nanoparticles, Interfacial engineering, Lithium-ion conductivity, Chloride solid electrolytes