In a striking advancement poised to revolutionize the field of quantum technologies, researchers have introduced a cutting-edge 3D printing method for fabricating miniature ion traps with unprecedented precision and scalability. Ion traps serve as the backbone of many quantum information processing devices, precision measurement tools, optical clocks, and mass spectrometers. Despite their fundamental importance, the fabrication of these traps, especially in compact, scalable formats that maintain strong confinement and operational versatility, has remained a persistent challenge. Now, leveraging two-photon polymerization (2PP), the research team has demonstrated a powerful route to overcome these limitations, potentially transforming how quantum devices are created and deployed on chip-scale platforms.

Ion traps operate by using carefully designed electric fields to confine charged particles—ions—in space. This capability underpins a variety of applications, ranging from the manipulation of quantum bits (qubits) in quantum computing to enabling ultra-precise spectroscopy and timekeeping in optical clocks. Traditionally, macroscopic traps have been machined with high precision to ensure robust three-dimensional confinement of ions. While extremely effective in laboratory settings, these large-scale devices pose significant obstacles when it comes to miniaturization and integration into scalable quantum information architectures. On the other hand, microfabricated surface traps manufactured using photolithography have gained traction for scalability, but they often sacrifice the radial confinement strength available in 3D geometries, limiting their performance.

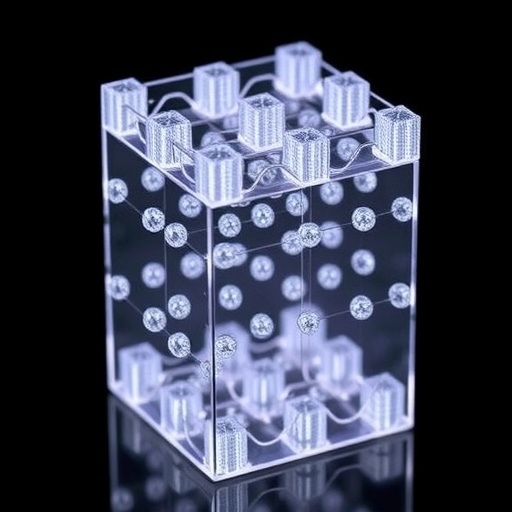

The newly reported approach elegantly bridges this divide by employing two-photon polymerization, a high-resolution 3D printing technique, to directly fabricate complex, high-aspect-ratio 3D electrode structures on a microscopic scale. Unlike traditional lithographic methods constrained to planar layers, 2PP allows true three-dimensional patterning of electrodes with nanometer precision, thereby restoring the optimal trapping potential shapes needed for high-fidelity ion confinement. This breakthrough is not only a leap in fabrication technology but also opens new opportunities for tailoring trap geometries unobtainable with conventional machining or lithography.

In their experiments, the researchers successfully trapped calcium ions in the 3D-printed micro ion traps, demonstrating radial trap frequencies spanning from 2 MHz up to an impressive 24 MHz. Such strong confinement is critical as it reduces the motional heating of ions, which typically hinders quantum operations. By confining ions more tightly, the system relaxes the requirements for advanced ion cooling techniques, allowing the team to achieve high-quality Rabi oscillations using only Doppler cooling—a relatively simple and widely used method. This simplification is expected to accelerate the deployment of quantum computing modules by reducing operational complexity.

Moreover, the team showcased a two-qubit gate operation with a Bell-state fidelity of 0.978 ± 0.012, a metric indicating that quantum entanglement between two ions was created with high accuracy. Achieving such fidelity in a miniaturized 3D-printed trap confirms that these devices maintain, and potentially exceed, the performance standards of larger, traditionally machined traps. This fidelity benchmark is critical because high entanglement fidelity is necessary for error-corrected quantum computing and the realization of scalable quantum networks.

One of the most profound impacts of adopting 3D printing technologies in ion trap fabrication lies in the drastically expanded design freedom. Conventional machining and lithographic processes impose strict constraints on electrode geometry and size, often leading to compromises between scalability and ion confinement quality. With 2PP-enabled printing, ion traps can be produced as complex arrays with precise control over electrode shapes and spacing. This flexibility paves the way for integrated quantum processors that can house many qubits while optimizing each trap for specific performance parameters.

The implications extend beyond quantum computing. Precision metrology applications, including frequency standards and fundamental physics experiments that rely on trapped ions, stand to gain from miniaturized yet highly sophisticated trap designs. For instance, optical clocks that require stable and isolated ion confinement could become more compact and accessible. Likewise, the manufacturing of advanced mass spectrometers might benefit from traps designed with tailor-made fields to improve resolution and sensitivity.

Notably, the use of 3D printing expedites the fabrication timeline from weeks or months to potentially days. This rapid prototyping capability accelerates research and development cycles, enabling swift iteration on trap design and immediate experimental testing. Consequently, novel ion-trap architectures can be explored with minimal delay, catalyzing innovation throughout the quantum technology community.

Despite these impressive achievements, integrating 3D-printed ion traps with existing electronic and optical control hardware demands further engineering efforts. The printed electrodes require reliable electrical connectivity and stable operation under ultra-high vacuum environments essential for ion trapping experiments. Nonetheless, the early success demonstrated by the research team showcases the feasibility of addressing these interface challenges.

The scalability demonstrated by printing large arrays of micro traps also suggests promising pathways toward modular quantum processors. Arrays of ions, each confined and manipulated in tailored microtraps, could serve as building blocks for distributed quantum computing architectures or quantum simulators. Additionally, the miniaturized form factor may facilitate integration with photonic circuits necessary for quantum communication channels.

This intersection of high-resolution 3D fabrication and ion trapping technology epitomizes a convergence of advanced manufacturing with frontier quantum science. The ability to fabricate intricately structured, microscopic electrostatic potentials with nanometer control heralds a new era of experimental versatility. Researchers and engineers are now empowered to design ion traps not only to meet existing performance standards but to innovate and redefine them.

As quantum information processing inches closer to practical realization, the role of precision-engineered hardware becomes increasingly central. The demonstrated advancement in 3D-printed micro ion traps ushers in a new paradigm where quantum devices can be rapidly manufactured, customized, and scaled without compromise. The possibilities unlocked by this technology extend from improving fundamental physics experiments to enabling transformative quantum computing platforms that harness individual ions as robust, high-coherence qubits.

Looking forward, further optimization of material properties, electrical interfacing, and integration with microwave and laser control systems will likely accelerate the transition of 3D-printed ion traps from laboratory curiosities to mainstream components in commercial quantum devices. The fusion of additive manufacturing with quantum technology exemplifies the creative ingenuity driving the next generation of scientific breakthroughs.

In conclusion, the pioneering research in 3D-printed micro ion traps marks a significant milestone toward scalable, high-performance quantum information technologies. By marrying the superior radial confinement of three-dimensional electrode geometries with the miniaturization and design freedom afforded by two-photon polymerization, this work charts a promising course for the future of quantum hardware fabrication. Ultimately, these advances bring us closer to realizing practical quantum computing systems that can be readily manufactured and deployed on a large scale.

Subject of Research: Advanced fabrication technology for micro ion traps aimed at quantum information applications

Article Title: 3D-printed micro ion trap technology for quantum information applications

Article References:

Xu, S., Xia, X., Yu, Q. et al. 3D-printed micro ion trap technology for quantum information applications. Nature (2025). https://doi.org/10.1038/s41586-025-09474-1

Image Credits: AI Generated